Imagine this: a crucial machine breaks down, halting your entire production line. Sound familiar? ????

What if AI could predict these meltdowns and prevent them altogether? ????

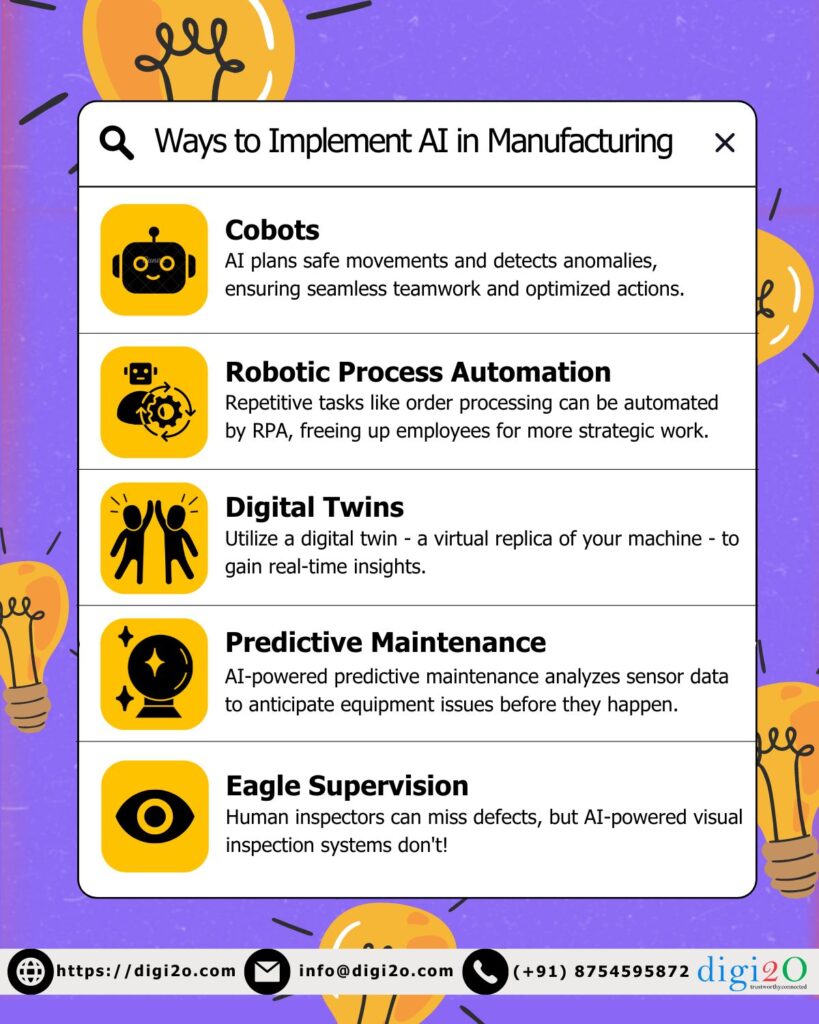

According to a recent TechTarget feature, manufacturers are leveraging AI in powerful ways to boost efficiency, reduce costs, and stay ahead of the curve. Here are 5 examples you can implement today ⭐:

Cobots????: Your AI-Powered Teammate

Empower your assembly line with intelligent cobots! These collaborative robots leverage AI for object recognition, adapting to various parts. AI also plans safe movements and detects anomalies, ensuring seamless teamwork and optimized actions. This frees up your team for more complex tasks, while guaranteeing reliable cobot assistance.

RPA Takes Over Tedious Tasks with AI's Help????

Repetitive tasks like order processing can be automated by RPA, freeing up employees for more strategic work. AI enhances this by enabling bots to learn and improve accuracy, handle exceptions, and even process unstructured data like emails. This powerful combination maximizes efficiency and lets your team focus on higher-value tasks.

Digital Twins????????????: Know Your Machines Inside Out with AI

Utilize a digital twin - a virtual replica of your machine - to gain real-time insights. AI analyzes sensor data from both, predicting potential failures and optimizing performance. This continuous learning loop ensures proactive maintenance, maximizing equipment lifespan and operational efficiency. Imagine a real-time health check for your machines, fueled by AI's predictive power.

Predictive Maintenance????: See the Future (of Your Machines)

Never be caught off guard by a machine failure again! AI-powered predictive maintenance analyzes sensor data to anticipate equipment issues before they happen. This allows you to schedule maintenance proactively, avoiding downtime and saving money.

AI Inspects with Eagle Eyes????️

Human inspectors can miss defects, but AI-powered visual inspection systems don't! These systems use machine vision cameras to detect flaws in products with incredible accuracy. This ensures you deliver only the highest quality products to your customers.

Ready to revolutionize your factory floor? This is just the tip of the AI iceberg! ✨

The integration of Artificial Intelligence (AI) into manufacturing processes has brought about a significant transformation in the industry landscape. AI technologies offer unparalleled opportunities to enhance efficiency, quality control, and predictive maintenance in manufacturing operations. By harnessing the power of AI, manufacturers can streamline processes, reduce costs, and stay competitive in an ever-evolving market.

In the realm of manufacturing, cobots - collaborative robots powered by AI - are revolutionizing assembly lines. These intelligent machines work alongside human operators, performing tasks that require precision and dexterity. By leveraging AI for object recognition and safe movement planning, cobots ensure seamless collaboration with human workers. This not only boosts productivity but also enhances safety in the workplace.

Robotic Process Automation (RPA) combined with AI is automating repetitive tasks that were once time-consuming for human workers. From order processing to data entry, RPA systems equipped with AI capabilities can handle a myriad of tasks with speed and accuracy. This automation liberates human resources, allowing them to focus on strategic initiatives that drive innovation and business growth.

Digital twins, virtual replicas of physical machines, offer manufacturers invaluable insights into their operations. By integrating AI algorithms, these digital counterparts can analyze real-time sensor data to predict potential failures and optimize performance. This proactive approach to maintenance not only minimizes downtime but also extends the lifespan of equipment, ultimately enhancing operational efficiency.

Predictive maintenance powered by AI is transforming the way manufacturers approach equipment upkeep. By analyzing sensor data and machine learning algorithms, AI can anticipate potential issues before they occur. This foresight enables proactive maintenance scheduling, reducing unplanned downtime and saving costs associated with emergency repairs. Manufacturers can now keep their production lines running smoothly with minimal disruption.

AI-powered visual inspection systems are raising the bar for quality control in manufacturing. Equipped with machine vision cameras and advanced algorithms, these systems can detect even the smallest defects with unparalleled accuracy. By ensuring the integrity of every product that leaves the factory floor, manufacturers can uphold their reputation for delivering high-quality goods to consumers.

As the manufacturing industry continues to evolve, embracing the AI revolution is essential for staying competitive in a rapidly changing landscape. By implementing AI technologies such as cobots, RPA, digital twins, predictive maintenance, and AI inspection systems, manufacturers can unlock new levels of efficiency, quality, and innovation. The future of manufacturing is AI-powered, and those who adapt will thrive in the factory of the future.

Ready to revolutionize your factory floor with AI? Explore the possibilities and transform your manufacturing processes today!

Designed by W3Squad