In the fast-paced world of manufacturing, every second counts. The last thing you need is a sudden breakdown disrupting your operations. But fear not! The magic of IoT (Internet of Things) is here to save the day. Let's embark on a journey to seamlessly integrate IoT devices into your industrial processes and revolutionize your production line!

Defining Your Goals

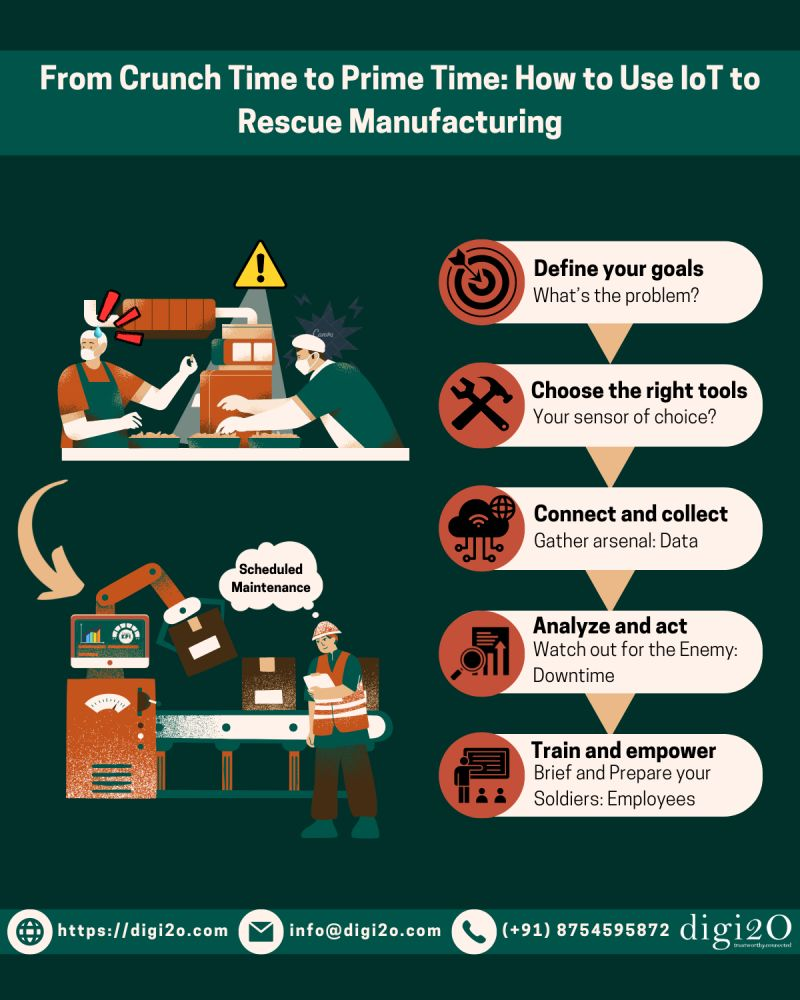

Before diving into the world of IoT, it's crucial to define your objectives. What challenges are you facing in your manufacturing process? Are you struggling with machine downtime, inefficient inventory management, or unpredictable maintenance costs? By clearly identifying your goals, you can tailor your IoT implementation to address specific pain points.

Key Point: Define clear objectives to guide your IoT integration process.

Choosing the Right Tools

With a plethora of IoT devices available in the market, selecting the right tools can be daunting. From sensors to gateways, each component plays a crucial role in capturing and transmitting data. Consider factors such as compatibility, reliability, and scalability when choosing your IoT infrastructure.

Key Point: Research and select IoT devices that align with your requirements and budget.

Connecting and Collecting

Once you've chosen your IoT devices, it's time to connect them to your existing network and start collecting data. Whether through Wi-Fi, Bluetooth, or cellular connectivity, ensure seamless communication between devices. Establish robust data collection mechanisms to gather insights in real-time.

Key Point: Establish a secure and reliable network for seamless data collection from IoT devices.

Analyzing and Acting

Data without analysis is like a puzzle without solving. Leverage advanced analytics tools to process the data collected from your IoT devices. Identify patterns, detect anomalies, and derive actionable insights to optimize your manufacturing processes. From predictive maintenance to demand forecasting, data-driven decisions can drive efficiency and profitability.

Key Point: Utilize analytics tools to transform raw data into actionable insights for informed decision-making.

Training and Empowering

Empower your workforce to embrace the IoT revolution through comprehensive training programs. Educate employees on the benefits of IoT integration and provide hands-on experience with IoT devices. Foster a culture of innovation and continuous learning to ensure smooth adoption and utilization of IoT technologies.

Key Point: Invest in training to equip your team with the skills and knowledge needed for successful IoT implementation.

Real-time Insights: The Power of IoT

IoT enables real-time monitoring of machine health, inventory levels, and production metrics. With instant access to critical data, manufacturers can make proactive decisions to optimize efficiency and minimize downtime. Imagine having eyes everywhere in your factory, ensuring smooth operations round the clock.

Predictive Maintenance Made Easy

Gone are the days of reactive maintenance. IoT empowers manufacturers to anticipate equipment failures before they occur. By analyzing sensor data for early warning signs, predictive maintenance schedules can be implemented, reducing costly downtime and extending asset lifespan.

Smarter Supply Chains with IoT

IoT revolutionizes inventory management by providing real-time visibility into stock levels and consumption patterns. Automated replenishment systems ensure that essential parts are always available when needed, minimizing production delays and excess inventory costs.

Enhancing Efficiency with IoT

From streamlining production workflows to optimizing energy usage, IoT offers endless possibilities for enhancing efficiency in manufacturing. By leveraging data-driven insights, manufacturers can identify bottlenecks, eliminate waste, and continuously improve processes for maximum productivity.

Overcoming Challenges

Despite its numerous benefits, IoT integration comes with its own set of challenges. From cybersecurity threats to interoperability issues, manufacturers must navigate various obstacles to ensure successful implementation. However, with careful planning and strategic investments, these challenges can be overcome, unlocking the full potential of IoT in industrial processes.

Designed by W3Squad