In the dynamic realm of manufacturing, efficiency is paramount. A single glitch in the production line can cascade into significant downtime, wreaking havoc on schedules and profitability. Traditional maintenance practices, reliant on fixed schedules or reactive responses, are no longer sufficient to meet the demands of modern manufacturing. Here's where predictive maintenance (PdM) emerges as a game-changer, ushering in a new era of proactive and streamlined operations.

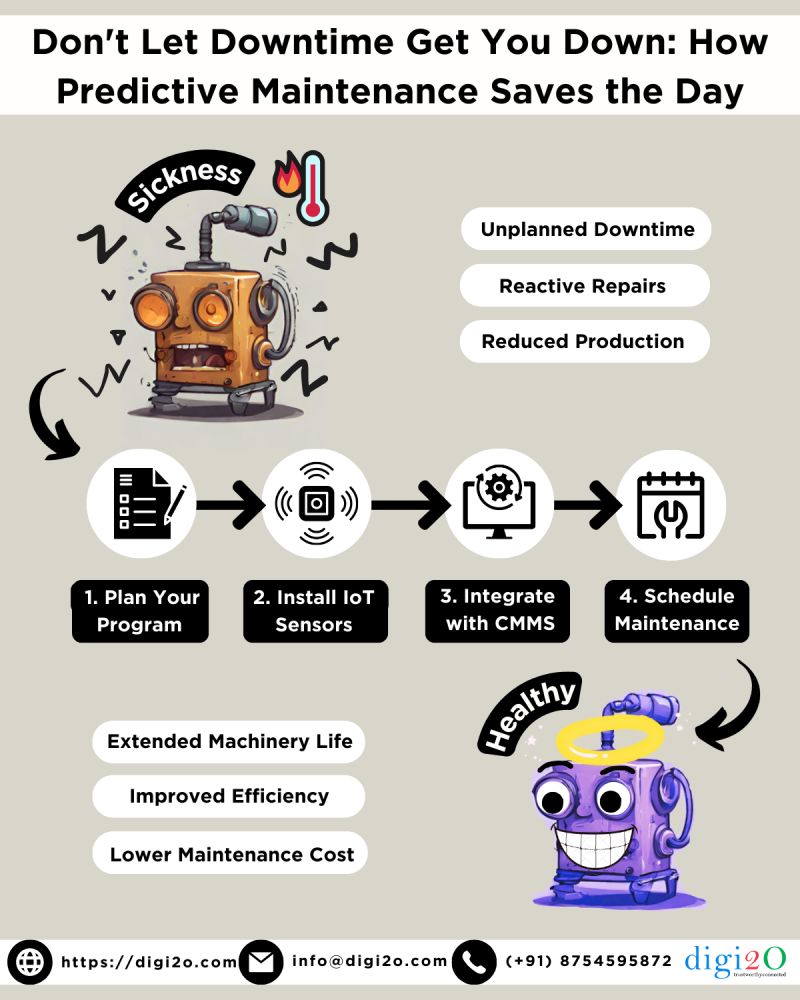

Unplanned downtime is the bane of manufacturing existence, causing disruptions that ripple through the entire supply chain. Beyond the direct financial implications, such as lost production and idle manpower, the intangible costs of damaged reputation and diminished customer confidence loom large. Outdated maintenance strategies, marked by a lack of foresight and reliance on manual interventions, exacerbate these challenges. Reactive repairs, often prompted by catastrophic failures, not only inflate maintenance expenditure but also compromise operational efficiency.

Enter predictive maintenance, a proactive approach empowered by IoT sensors and AI-driven analytics. Unlike traditional methods, PdM doesn't merely react to equipment malfunctions; it anticipates them, leveraging real-time data insights to forestall potential breakdowns. By harnessing a myriad of metrics, from vibration patterns to temperature fluctuations, PdM transforms equipment health monitoring into a predictive science.

The adoption of predictive maintenance yields a plethora of advantages, amplifying the operational prowess of manufacturing facilities:

By detecting anomalies in equipment performance at their nascent stages, PdM empowers manufacturers to intervene proactively, averting full-scale breakdowns. Consequently, unplanned downtime is minimized, ensuring uninterrupted production schedules and enhanced customer satisfaction.

The shift from reactive to proactive maintenance translates into substantial cost savings. Investments in predictive analytics and IoT infrastructure pale in comparison to the exorbitant expenses incurred during emergency repairs. Moreover, predictive maintenance optimizes resource allocation, ensuring that maintenance activities are targeted and efficient.

PdM optimizes equipment performance by identifying and rectifying inefficiencies before they escalate. By streamlining maintenance schedules and prioritizing interventions based on data-driven insights, manufacturers can unlock newfound levels of productivity and operational agility.

Early detection of potential malfunctions allows for timely interventions, thereby extending the lifespan of critical assets. By addressing issues preemptively, manufacturers can mitigate wear and tear, preserving the integrity of machinery and deferring costly replacements.

In the realm of food and beverage production, where precision is paramount and downtime is intolerable, the integration of predictive maintenance has yielded remarkable results. Consider a chocolate factory, where the seamless operation of churners and conveyors is non-negotiable. By deploying IoT sensors to monitor equipment health and leveraging AI algorithms to anticipate maintenance needs, manufacturers can ensure the uninterrupted flow of production, safeguarding both quality and efficiency.

The transition to predictive maintenance necessitates a strategic approach, encompassing meticulous planning and seamless execution:

Begin by identifying the key areas of focus for predictive maintenance implementation. Analyze historical maintenance data to pinpoint recurring issues and prioritize equipment assets based on criticality and operational impact.

Equip your machinery with a comprehensive array of IoT sensors capable of capturing relevant performance metrics. From temperature sensors to acoustic monitors, ensure that your sensor network is tailored to the unique requirements of your manufacturing environment.

Centralize and analyze the deluge of data generated by IoT sensors through a robust Computerized Maintenance Management System (CMMS). Leverage AI-powered analytics tools to derive actionable insights and facilitate data-driven decision-making.

Leverage predictive insights to overhaul traditional maintenance schedules, transitioning from reactive to proactive interventions. Implement predictive maintenance routines based on equipment health forecasts, optimizing resource allocation and minimizing downtime.

In conclusion, the adoption of predictive maintenance heralds a paradigm shift in manufacturing operations, empowering organizations to transcend the limitations of traditional maintenance practices. By harnessing the power of IoT sensors and AI-driven analytics, manufacturers can transform reactive firefighting into proactive problem-solving, paving the way for enhanced efficiency, productivity, and competitiveness.

Ready to embark on your predictive maintenance journey? Embrace the future of manufacturing today!

Designed by W3Squad