I have been in conversation with a large manufacturing company who need support for an assembly line test equipment and data analytics. (This is an interesting story by itself and I shall talk about it in a later article.)

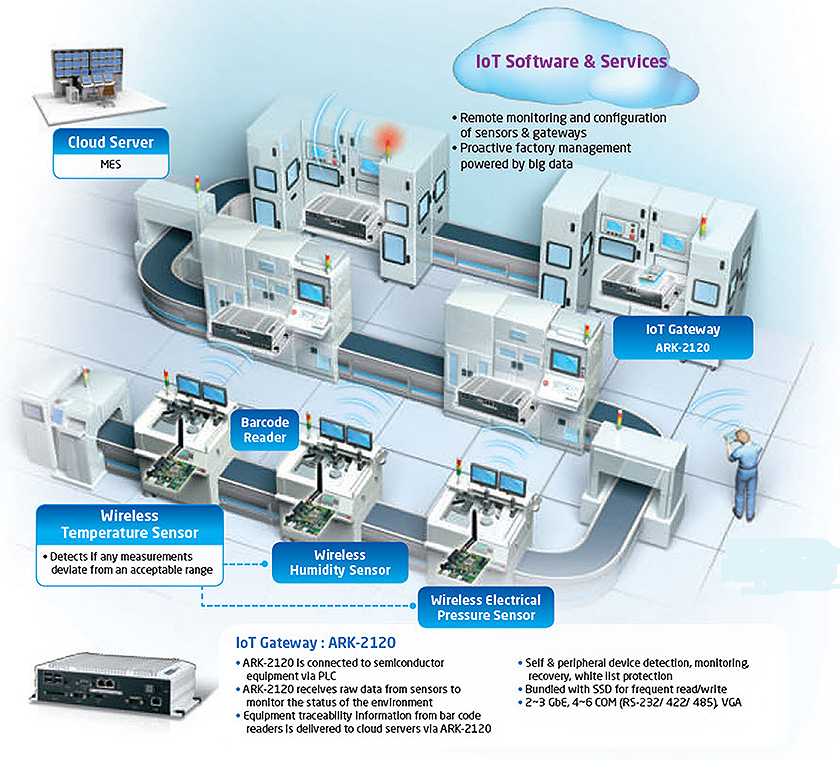

I came to know recently from them that a team there is also looking to retrofit solutions to their production machines on the shop floor to collect real-time data.

There is a need of retrofitting IoT solutions to their existing machines since the equipment OEMs may not have necessarily designed their machines with these solutions. Note that only very lately the equipment manufacturers are putting strategies in place to build ‘connected’ machines.

There is a strong case for equipment owners to gather intelligence from their ‘connected’ machines and ‘listen’ to what these machines are ‘saying’. This helps you to truncate costs in many ways. You can prevent breakdowns and increase up time. You can ensure optimal inventory and usage of spares. You can plan and schedule your equipment usage better. You can run an effective maintenance department with better planning of maintenance personnel. Better life of your machines is likely to reduce your future capital expenses. The connected intelligence of interconnected machines can even fully automate your shop floor. The world is inexorably moving in this direction.

Per a recent survey in the US, nearly 90% of the manufacturers are using or exploring the use of IoT technology to enhance operations.

There is a happy spin-off of investing in retrofitting IoT solutions to your machines. The data that you gather over a period is a goldmine for the OEMs who have built those machines. The analytics from this data can help the OEMs design and build machines that are of improved quality, usability, reliability and safety.

Such information from the field can throw light on usage duration, user behavior, user preferences, usage environment, failure modes, mean time between and to failure, mean time to repair, efficiency of the system and the sub-systems and a host of other parameters that can provide significant inputs for design and product quality improvements and eventually customer delight for the OEMs.

So, there is a very strong case for equipment owners to collaborate with their equipment suppliers and share with them the intelligence gathered over time. The OEMs will be happy to pay for such a service. Such a symbiotic arrangement is a win-win for both parties.

The survey quoted earlier also mentions that 86% of the product manufacturers in the US who were surveyed have either built or started building IoT solutions within their products precisely for the reasons quoted above. Now, how good it would be for the equipment owners to feed this ready information back to them?

To produce the intelligence from the data the equipment owners do not need to invest in a department full of data scientists! Such services are available on demand and they can utilize them on a case to case basis. Perhaps the company they engage to retrofit the IoT solutions can help on this. (This is assuming that the retrofitting is not being done in-house.)

Designed by W3Squad