Did you know that Digital Performance Management or DPM has been found to help companies to boost productivity between 40 and 70%?

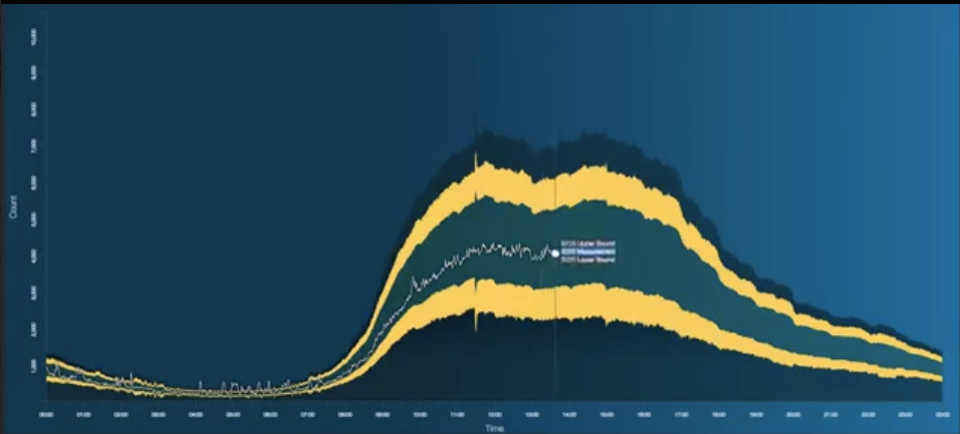

DPM, supported by IIoT, is making information transparent, improving accountability and helping factories make better and faster decisions. Dashboards from the shop floor and the field on metrics such as production and productivity, breakdowns and stoppages, quality and scrap, can now be made available on floor display screens and on mobile phones.

No longer do you need to maintain manual logs or tons of spreadsheets. Data moves directly from machines to your dashboards without painful manual intervention. Behind this remarkable transformation is the unquestionable role of sensors and PLCs attached to your equipment.

PLCs or Programmable Logic Controllers are the brains behind most modern machines. They are ubiquitous in all types of industries. In fact, you cannot imagine any modern factories without them. They are small computers that are used to sense various operational parameters and control machine operations. A PLC is quite integral to the automation of a machine.

PLCs are a repository of a wealth of real time data from machines that can make Digital Performance Management happen. Though, DPM is not a panacea for the COVID and post-COVID world, it can be a major game changer for factory managers by helping them manage their work remotely and lowering stress.

If you are a factory manager and looking for some affordable but high impact solutions in your digitalization journey, we recommend that you seriously consider implementing DPM.

We, at Digi2O, have created intelligent digital systems that support informed and accelerated decision making and which improve the efficient use of your assets. This can be used to interface with your machines and PLCs to support you in your DPM implementation effort. Please feel free to write back to me or request for a call back if you have any questions on how to implement DPM in your organization.

Designed by W3Squad