In the ever-evolving landscape of manufacturing, a powerful synergy between human workers and machines has emerged as a transformative force. The advent of Smart Factories has ushered in an era where artificial intelligence and robotics are revolutionizing our approach to production. This paradigm shift transcends mere technological advancements; it signifies an enhancement in collaboration between humans and machines, driving unprecedented efficiency, safety, and innovation.

1. Evolution of Smart Factories: A Technological Marvel

Smart Factories represent the pinnacle of manufacturing evolution. These facilities leverage advanced technologies such as artificial intelligence (AI) and robotics to optimize processes and streamline production. The integration of these technologies into the manufacturing workflow has led to remarkable improvements in efficiency and precision.

1.1 Efficiency Through Precision: The Heart of Smart Factories

One of the key hallmarks of Smart Factories is their ability to leverage AI and robotics to optimize processes, thereby reducing errors and increasing precision. Predictive maintenance and quality control are areas where these technologies shine. AI algorithms can predict equipment failures before they occur, enabling proactive maintenance that minimizes downtime. Additionally, robotic systems equipped with advanced sensors can ensure that every product meets the highest quality standards. This collaboration between human expertise and machine efficiency leads to products that are not only reliable but also of exceptional quality.

1.2 Enhanced Safety Measures: Protecting the Workforce

Safety is paramount in any manufacturing setting. Smart Factories address this concern by incorporating AI-powered sensors and robots that are capable of undertaking dangerous tasks. By delegating hazardous activities to machines, human workers can focus on tasks that require creativity, critical thinking, and problem-solving abilities. This ensures a safer working environment, reducing the risk of accidents and injuries.

2. Real-time Insights: The Power of Data in Manufacturing

In the realm of Smart Factories, data is king. AI-driven analytics provide real-time insights into operations, empowering human workers to make data-driven decisions. This collaboration between humans and machines not only enhances productivity but also enables the workforce to adapt swiftly to changing market demands. By harnessing the power of data analytics, manufacturers can optimize production schedules, predict market trends, and minimize waste, thereby ensuring a competitive edge in the market.

3. Upskilling Opportunities: Nurturing Talent for the Future

As machines take on repetitive and mundane tasks, human workers are presented with unique upskilling opportunities. Automation frees up valuable time and resources, allowing employees to focus on acquiring new skills and competencies. This continuous learning environment fosters career growth and job satisfaction among the workforce. Manufacturers can invest in training programs that enhance the technological proficiency of their employees, ensuring that they remain relevant and adaptable in an ever-changing industry.

4. Sustainability Impact: Smart Factories and Environmental Responsibility

In the pursuit of a sustainable future, Smart Factories play a pivotal role. Efficient resource utilization driven by AI reduces waste and energy consumption significantly. Machines equipped with sensors can optimize energy usage, ensuring that factories operate at peak efficiency while minimizing their carbon footprint. This collaboration between humans and machines aligns seamlessly with the global commitment to environmental conservation, making Smart Factories a beacon of sustainable manufacturing practices.

5. Digi2O: Pioneering the Smart Factory Revolution

At Digi2O, we stand at the forefront of this transformative journey. Our Smart Factory initiatives exemplify the power of human-machine collaboration. By integrating cutting-edge technologies and fostering a culture of innovation, we have redefined the manufacturing landscape. Through our commitment to excellence, efficiency, and sustainability, we continue to set new benchmarks in the industry.

6. Embracing the Future Together: A Call to Action

The future of manufacturing is undeniably intertwined with the collaboration between humans and machines. As we stand on the precipice of a new industrial revolution, it is imperative that businesses, policymakers, and educators join hands to nurture this collaboration. By investing in research and development, supporting educational initiatives, and creating conducive regulatory frameworks, society can harness the full potential of Smart Factories.

7. Conclusion: A Harmonious Future Beckons

In conclusion, the future of manufacturing lies in the harmonious collaboration between humans and machines. Smart Factories, powered by AI and robotics, represent the epitome of this collaboration, driving efficiency, safety, and innovation to unprecedented heights. As we embark on this transformative journey, it is essential to recognize the immense possibilities that lie ahead. By embracing the synergy between human expertise and machine efficiency, we can create a manufacturing ecosystem that is not only highly productive but also sustainable and socially responsible.

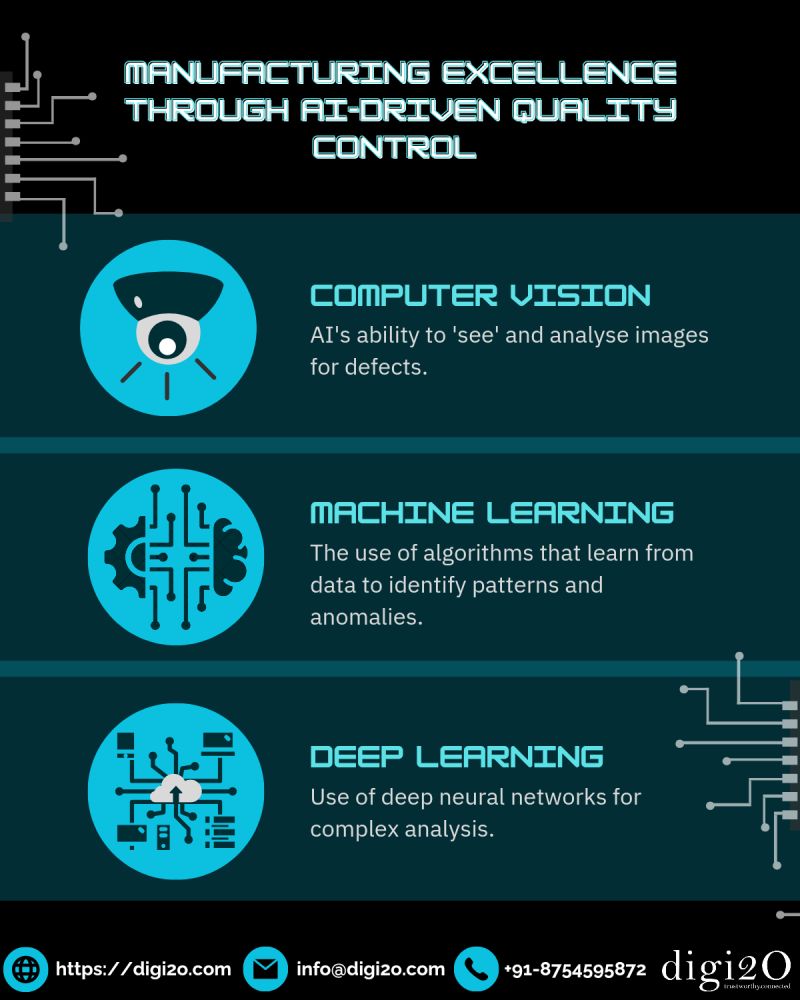

At Digi2O, we are dedicated to pushing the boundaries of innovation in manufacturing. Today, we are thrilled to unveil how Artificial Intelligence (AI) and cutting-edge computer vision technologies are reshaping quality control and defect detection in our production processes. Join us on this journey of manufacturing excellence empowered by AI, and discover how these advancements are setting new standards in precision, reliability, and efficiency.

Sharper Eyes, Better Quality?️

With the power of AI and computer vision, we've equipped our manufacturing process with a pair of "supercharged" eyes. These technologies meticulously scan and analyze every product, detecting even the most minuscule anomalies that might escape the human eye. Imagine a hairline fracture, nearly invisible to us, being swiftly pinpointed by AI-powered quality checks. This level of precision ensures that every product leaving our facility meets the highest standards of quality.

Human-AI Synergy??

AI systems work hand-in-hand with our skilled technicians, creating a seamless synergy that combines the prowess of artificial intelligence with the refined judgment of experienced professionals. This partnership forms an unbeatable team, guaranteeing that no product falls short of perfection. Our technicians leverage AI as a powerful tool that enhances their ability to make informed decisions, resulting in consistently flawless output.

Boosting Efficiency and Reliability?

By harnessing AI for quality control, we don't just elevate precision; we also significantly increase efficiency. This means faster turnaround times without compromising quality. Imagine reducing production delays, eliminating defects, and ensuring that your customers receive products that stand the test of time. It's a win-win situation for your business and your valued customers.

The Future of Manufacturing, Today?

Welcome to the future of manufacturing, where AI reigns supreme. Embracing AI to automate your quality control processes isn't just a leap forward; it's your indispensable competitive advantage. In today's fast-paced world, staying ahead of the curve is essential. AI-driven quality control is not a luxury; it's a necessity to thrive in the ever-evolving landscape of manufacturing.

The future of manufacturing is at your doorstep, and it's AI-driven. Embrace the future today and redefine what's possible. Reach out to us to discover how AI can revolutionize your quality control processes and propel your business to the forefront of innovation.

Don't settle for tomorrow when you can embrace it today with AI-driven quality control. Your future starts now!

Conclusion

In conclusion, Digi2O is at the forefront of leveraging AI and computer vision to transform manufacturing quality control. Our commitment to excellence, combined with the power of AI, ensures that your products meet the highest standards of quality and reliability. Embrace the future of manufacturing today and gain a competitive edge that sets you apart in the industry. Contact us to explore how AI-driven quality control can revolutionize your production processes and drive innovation in your business. Don't wait for tomorrow; seize the opportunities of today with Digi2O's AI-driven solutions.

Ever wondered how AI can predict when machinery will fail??

Here, we are excited to take you on a journey into the heart of AI-driven predictive maintenance, revealing how it transforms raw data into invaluable predictions for machinery breakdowns?

Data Collection and Preprocessing?

It all starts with data, lots of it. In the realm of predictive maintenance, data is king. Sensors, IoT devices, and other data sources continuously capture a treasure trove of information, including temperature, vibration, pressure, and operational parameters from machinery. But this raw data isn't immediately ready for AI wizardry. It undergoes a meticulous process known as data preprocessing.

Cleaning the Data: Imagine this data as a river of information. But in this river, there are stones and debris noise and anomalies that can lead to incorrect predictions. To ensure that the algorithms operate on accurate and reliable information, we meticulously clean the data. This is like removing the pebbles from the river to make it flow smoothly.

Feature Engineering?

Now that we have our pristine data, the next step is feature engineering. This is where we craft the building blocks that AI will use to make predictions.

Selecting Relevant Attributes: Think of feature engineering as selecting the right ingredients for a recipe. We have domain experts who understand the machinery inside out, and they identify which aspects of the data are most indicative of machinery health. These attributes are then carefully chosen to feed into the predictive algorithms.

Algorithm Selection✅

With our data prepared and our features selected, it's time to choose the right algorithm. The choice of algorithm depends on the nature of the problem at hand. In the world of predictive maintenance, we have a toolbox of powerful options.

Machine Learning Techniques: These include Random Forests, Support Vector Machines, or deep learning methods like recurrent neural networks (RNNs) and Long ShortTerm Memory (LSTM) networks for timeseries data. It's like selecting the best tool for the job, and our experts are wellversed in making that choice.

Model Training?

Now comes the training phase. Our algorithms are like eager students in a classroom, ready to learn from historical data. They want to understand the relationships between features and the occurrence of machinery breakdowns.

Learning from Historical Data: During this phase, the algorithms adjust their internal parameters to minimize prediction errors. It's like refining their skills over time. They learn to recognize complex patterns and correlations in the data. Large datasets, often collected over an extended period, are crucial for training accurate models. It's like gaining wisdom through experience.

RealTime Monitoring?️

Once our predictive models are trained, they become vigilant sentinels integrated into the production environment. They continuously monitor machinery in realtime, 24/7.

Constant Vigilance: These algorithms are like tireless guards, comparing incoming data with the patterns they've learned. Any deviations, even the slightest blip, trigger alerts of potential breakdowns. It's akin to having a team of experts on watch around the clock.

Predictive Insights?

Predictive maintenance doesn't stop at issuing warnings about imminent failures. It provides invaluable insights into the probability and severity of potential issues.

Prioritizing Actions: By analyzing the output of the algorithms, maintenance teams can prioritize actions. It's like having a crystal ball that not only predicts the future but also suggests what actions to take. Whether it's scheduling maintenance during planned downtime or replacing a critical component, these insights are gold for businesses.

In a nutshell, the inner workings of predictive algorithms are a symphony of data collection, preprocessing, feature engineering, machine learning, and realtime monitoring. It's a complex orchestration of technology and expertise, all aimed at ensuring machinery breakdowns become a thing of the past, maximizing productivity in the era of Industry 4.0✨

Key Takeaways?

Data is the Foundation: Without quality data, predictive maintenance wouldn't be possible. It all starts with thorough data collection and cleaning.

Feature Engineering Matters: Selecting the right attributes to feed into the algorithms is crucial. It's like choosing the right ingredients for a recipe.

Algorithm Selection is Strategic: Different problems require different algorithms. The choice of algorithm is like picking the right tool for the job.

Continuous Learning: Algorithms continuously learn from historical data, improving their predictive accuracy over time.

RealTime Monitoring: Predictive models become real-time guardians, alerting teams to potential issues as they happen.

Actionable Insights: Predictive maintenance doesn't just predict; it guides actions, helping businesses save time and resources.

In the rapidly evolving landscape of Industry 4.0, Artificial Intelligence (AI) has emerged as a transformative force, revolutionizing the way businesses operate and innovate. With this technological advancement, however, comes the imperative need for ethical considerations to safeguard against potential risks and biases. At the recent AI Safety Summit held in the United Kingdom, global leaders converged, highlighting the critical nature of this discourse. In this comprehensive exploration, we delve into the ethical dimensions of AI in Industry 4.0, examining key challenges and strategies for responsible implementation.

Understanding Ethical Challenges in AI Integration

In the heart of Industry 4.0, ethical challenges loom large, demanding our attention. Bias in algorithms, a pervasive concern, can perpetuate inequalities. In our quest for unbiased AI, we meticulously analyze the impact of conscious and unconscious biases on decision outcomes. Our commitment to transparency is unwavering, as we advocate for transparent AI decision-making processes that engender trust and credibility.

Confronting Bias in Algorithms: A Deep Dive

Bias in AI algorithms is a multifaceted issue that necessitates careful consideration. These biases, whether based on race, gender, or other factors, can infiltrate algorithms, resulting in skewed outcomes. We must confront these biases head-on. Through rigorous analysis and continuous scrutiny, we can identify and mitigate biases, ensuring fair and equitable AI applications. The implementation of strategies such as diverse dataset curation and bias detection algorithms is paramount to achieving this objective.

Unravelling Transparency: Fostering Trust through Explainable AI

Transparency forms the bedrock of responsible AI. In the labyrinth of complex algorithms, explainable AI emerges as a beacon, illuminating the path to understanding. We advocate for transparency in AI systems, ensuring that intricate algorithms are decipherable and accountable. Explainable AI allows us to demystify the decision-making process, instilling confidence in stakeholders and users alike.

Establishing Accountability: Ethical Standards in AI-driven Actions

Accountability stands as a cornerstone in the realm of AI. Establishing robust frameworks that hold organizations accountable for AI-driven actions is non-negotiable. Legal and ethical standards must intertwine seamlessly to create an environment where responsible AI flourishes. Best practices, coupled with stringent adherence to guidelines, bolster the foundation of accountability, paving the way for ethical AI integration.

Promoting Responsible Innovation in Industry 4.0

In the era of Industry 4.0, innovation is indispensable, but it must be tempered with responsibility. We spotlight pioneering companies that exemplify ethical AI practices. These trailblazers serve as beacons, illuminating the path for others to follow. Responsible innovation not only fosters positive change but also bestows a competitive advantage upon organizations. Embracing ethical practices is not just a moral imperative; it is a strategic necessity.

Join the Dialogue: Shaping a Future of Ethical AI in Industry 4.0

Join us in this transformative dialogue on LinkedIn Live as we navigate the complexities of ethical AI in Industry 4.0. Together, we will shape a future where innovation coexists harmoniously with ethics. Let us collectively work towards a world where AI serves humanity responsibly and equitably, forging a path toward a brighter, more ethical future.

? Ready to navigate the ethical frontiers of Industry 4.0? Let's lead the way together! ? EthicsInAI ResponsibleInnovation Industry4point0 AIethics TransparentAI AccountableAI InclusiveTech

Designed by W3Squad