The landscape of manufacturing has witnessed a profound shift over the past century with the advent of mass production, a paradigm that revolutionized efficiency and reduced costs. However, in our contemporary era, characterized by an unprecedented demand for individualized products, manufacturers are grappling with the challenge of meeting diverse and specific customer needs.

Embracing the Power of Artificial Intelligence (AI)

In this dynamic scenario, Artificial Intelligence (AI) has emerged as a transformative force, paving the way for a shift from mass production to customized mass production. The integration of AI into manufacturing processes brings a multitude of advantages, positioning it as the catalyst for the future of the industry.

Predicting Customer Preferences and Demand

One of the pivotal roles that AI plays in this transition is its ability to predict customer preferences and demand patterns. Through sophisticated algorithms, AI analyses vast datasets encompassing customer purchase history, online behavior, and social media interactions. This data driven approach enables manufacturers to anticipate what customers desire and when they will want it.

Optimizing Production Processes

AI's analytical prowess extends to the realm of production processes. By identifying and eliminating bottlenecks, improving efficiency, and reducing waste, AI optimizes manufacturing workflows. The result is a streamlined process that empowers manufacturers to produce customized products at scale without compromising cost*effectiveness. This optimization is not merely about reducing costs but also about ensuring a sustainable and environmentally conscious approach to production.

Task Automation for Enhanced Efficiency

Automation lies at the heart of AI's transformative impact on manufacturing. From design to quality control and shipping, AI can automate a myriad of tasks traditionally performed by human workers. This automation liberates human resources to focus on more creative and strategic aspects of production, fostering innovation and elevating the overall efficiency of the manufacturing process.

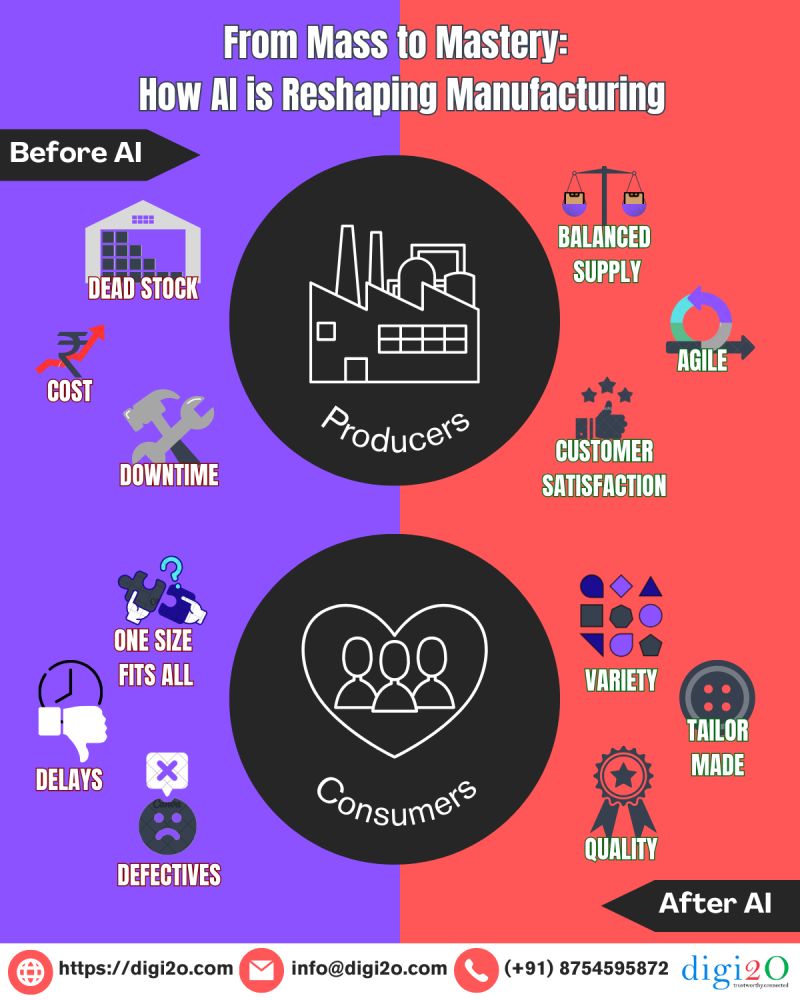

Benefits of AI*Enabled Customized Mass Production

For Manufacturers

* Increased Customer Satisfaction: The ability to deliver products tailored to individual preferences significantly enhances customer satisfaction and fosters brand loyalty.

* Reduced Costs: AI*driven optimization leads to cost reduction, making customized mass production economically viable for manufacturers.

* Improved Agility: AI equips manufacturers to respond swiftly to changes in customer demand, enhancing overall business agility.

For Consumers

* More Choices: AI*enabled customized mass production expands the array of choices available to consumers, ensuring a diverse range of products and services.

* Better Quality: Consumers receive products precisely tailored to their needs and preferences, elevating the overall quality of the goods they purchase.

* Lower Prices: As AI becomes more prevalent in customized mass production, economies of scale are expected to drive down the cost of personalized products and services, benefitting consumers.

The Transformative Impact of AI on Manufacturing

In summary, AI is ushering in a new era in the manufacturing industry by facilitating a shift from mass production to customized mass production. This transformation not only addresses the evolving demands of consumers but also brings a myriad of benefits to both manufacturers and end users alike.

As AI technology continues to evolve, the possibilities for innovative applications in manufacturing are boundless. The industry can anticipate a future where AI plays an even more central role in creating customized products and services at scale. The ongoing evolution of AI promises exciting opportunities for manufacturers to stay at the forefront of technological advancements.

Conclusion

In conclusion, the fusion of AI and manufacturing is not just a paradigm shift; it is a revolution. The transition from mass production to customized mass production, driven by AI, is unlocking unprecedented potential for the industry. As businesses embrace the power of AI, they position themselves to thrive in a market that demands not just products but experiences tailored to individual preferences.

The landscape of manufacturing has witnessed a profound shift over the past century with the advent of mass production, a paradigm that revolutionized efficiency and reduced costs. However, in our contemporary era, characterized by an unprecedented demand for individualized products, manufacturers are grappling with the challenge of meeting diverse and specific customer needs.

Embracing the Power of Artificial Intelligence (AI)

In this dynamic scenario, Artificial Intelligence (AI) has emerged as a transformative force, paving the way for a shift from mass production to customized mass production. The integration of AI into manufacturing processes brings a multitude of advantages, positioning it as the catalyst for the future of the industry.

Predicting Customer Preferences and Demand

One of the pivotal roles that AI plays in this transition is its ability to predict customer preferences and demand patterns. Through sophisticated algorithms, AI analyses vast datasets encompassing customer purchase history, online behavior, and social media interactions. This data driven approach enables manufacturers to anticipate what customers desire and when they will want it.

Optimizing Production Processes

AI's analytical prowess extends to the realm of production processes. By identifying and eliminating bottlenecks, improving efficiency, and reducing waste, AI optimizes manufacturing workflows. The result is a streamlined process that empowers manufacturers to produce customized products at scale without compromising cost*effectiveness. This optimization is not merely about reducing costs but also about ensuring a sustainable and environmentally conscious approach to production.

Task Automation for Enhanced Efficiency

Automation lies at the heart of AI's transformative impact on manufacturing. From design to quality control and shipping, AI can automate a myriad of tasks traditionally performed by human workers. This automation liberates human resources to focus on more creative and strategic aspects of production, fostering innovation and elevating the overall efficiency of the manufacturing process.

Benefits of AI*Enabled Customized Mass Production

For Manufacturers

* Increased Customer Satisfaction: The ability to deliver products tailored to individual preferences significantly enhances customer satisfaction and fosters brand loyalty.

* Reduced Costs: AI*driven optimization leads to cost reduction, making customized mass production economically viable for manufacturers.

* Improved Agility: AI equips manufacturers to respond swiftly to changes in customer demand, enhancing overall business agility.

For Consumers

* More Choices: AI*enabled customized mass production expands the array of choices available to consumers, ensuring a diverse range of products and services.

* Better Quality: Consumers receive products precisely tailored to their needs and preferences, elevating the overall quality of the goods they purchase.

* Lower Prices: As AI becomes more prevalent in customized mass production, economies of scale are expected to drive down the cost of personalized products and services, benefitting consumers.

The Transformative Impact of AI on Manufacturing

In summary, AI is ushering in a new era in the manufacturing industry by facilitating a shift from mass production to customized mass production. This transformation not only addresses the evolving demands of consumers but also brings a myriad of benefits to both manufacturers and end users alike.

As AI technology continues to evolve, the possibilities for innovative applications in manufacturing are boundless. The industry can anticipate a future where AI plays an even more central role in creating customized products and services at scale. The ongoing evolution of AI promises exciting opportunities for manufacturers to stay at the forefront of technological advancements.

Conclusion

In conclusion, the fusion of AI and manufacturing is not just a paradigm shift; it is a revolution. The transition from mass production to customized mass production, driven by AI, is unlocking unprecedented potential for the industry. As businesses embrace the power of AI, they position themselves to thrive in a market that demands not just products but experiences tailored to individual preferences.

In the dynamic realm of contemporary business, the fusion of Artificial Intelligence (AI) and inventory management has heralded a transformative era, reshaping conventional paradigms and redefining operational excellence. The synergy between AI and inventory management is not just a trend; it's a necessity. Businesses that harness the power of AI-driven solutions are finding innovative ways to optimize inventory levels and predict customer demand accurately, leading to substantial cost savings and a drastic reduction in stockouts. Let's embark on a comprehensive journey to decipher how AI technologies are ingeniously revolutionizing inventory management and demand forecasting, paving the way for a more efficient, customer-centric, and sustainable supply chain landscape.

1️⃣ Precise Demand Forecasting: A Data-Driven Revolution

At the heart of AI-driven inventory management lies the art of precise demand forecasting. AI equips businesses with the prowess to harness data-driven insights from historical patterns, market trends, and real-time factors. These insights enable algorithms to fine-tune forecasts with remarkable accuracy, mitigating the risks associated with overstocking and understocking items. By eliminating guesswork, businesses can strategically plan their inventory, ensuring that products are available when customers want them, thus bolstering customer satisfaction and loyalty.

2️⃣ Dynamic Inventory Optimization: Adapting to Market Dynamics

Gone are the days when inventory management relied on static, rule-based strategies. AI ushers in an era of dynamic inventory optimization, where inventory levels are continuously adjusted based on ever-changing market conditions and evolving customer preferences. This adaptability not only minimizes storage costs but also maximizes operational efficiency. Businesses can seamlessly align their inventory with customer demand, ensuring that resources are utilised optimally and wastage is minimized.

3️⃣ Preventing Stockouts: Anticipating Customer Needs

One of the cardinal sins in retail is a stockout – the unavailability of a desired product when a customer wants to purchase it. AI acts as a vigilant guardian, constantly monitoring inventory levels and alerting businesses to reorder before shelves run empty. By accurately anticipating customer needs, businesses can maintain an uninterrupted supply of products, thereby enhancing customer satisfaction and preventing revenue losses due to missed sales opportunities.

4️⃣ Reducing Costs: The AI-driven Efficiency Model

Sophisticated AI algorithms play a pivotal role in identifying cost-saving opportunities within the inventory management ecosystem. By optimizing storage space, minimizing waste, and streamlining supply chain processes, businesses can significantly reduce operational costs. These savings not only enhance profitability but also provide room for investments in innovation and customer experience, thus creating a positive feedback loop of efficiency and growth.

5️⃣ Enhanced Customer Satisfaction: Meeting Expectations Consistently

Accurate demand forecasting facilitated by AI translates into consistent customer satisfaction. When businesses consistently meet customer expectations regarding product availability, it fosters trust and loyalty. Satisfied customers are not only more likely to make repeat purchases but also become brand advocates, driving organic growth through positive word-of-mouth and online reviews. In the digital age, where customer experience is paramount, AI emerges as a powerful ally in ensuring customer delight.

6️⃣ Real-time Insights: Empowering Proactive Decision-making

AI-driven inventory management systems offer the invaluable gift of real-time insights. By providing instantaneous visibility into inventory data, these systems empower businesses with the ability to make proactive decisions. Whether it's responding swiftly to sudden market fluctuations or capitalizing on emerging trends, real-time insights enable businesses to stay ahead of the curve. In the fast-paced world of commerce, the ability to make informed decisions swiftly can be a game-changer, giving businesses a competitive edge.

Embracing the AI Revolution: Stories from Industry Leaders

Across diverse sectors, industry leaders are embracing the AI revolution in inventory management and demand forecasting. Retail giants are using AI-powered analytics to anticipate customer preferences and optimize their product offerings. Manufacturers are leveraging AI to streamline their supply chains, ensuring that raw materials are available when needed, and finished products are delivered on time. E-commerce platforms are using AI algorithms to recommend products to customers based on their browsing and purchase history, enhancing the personalization of the shopping experience. These stories of success underscore the transformative impact of AI on inventory management, inspiring other businesses to follow suit.

Conclusion: A Future of Efficiency, Innovation, and Customer Centricity

As we navigate the intricate landscape of modern commerce, AI stands as a beacon of efficiency, innovation, and customer centricity. The marriage between AI and inventory management not only optimizes operational processes but also elevates customer experience to unprecedented heights. Businesses that harness the power of AI are not just surviving; they are thriving, setting new benchmarks for excellence and redefining the future of supply chain operations.

In this era of rapid technological advancement, the question is not whether businesses can afford to embrace AI in inventory management and demand forecasting; it's whether they can afford not to. The choice is clear – adapt and thrive or stagnate and risk obsolescence. The future belongs to those who embrace change, innovate relentlessly, and prioritize the needs and expectations of their customers. As we stand on the cusp of a new industrial revolution powered by AI, the journey ahead promises to be exhilarating, challenging, and, above all, transformative. Let us embark on this journey together, unlocking the full potential of AI, and ushering in an era of unprecedented efficiency, innovation, and customer-centricity in the realm of inventory management and demand forecasting.

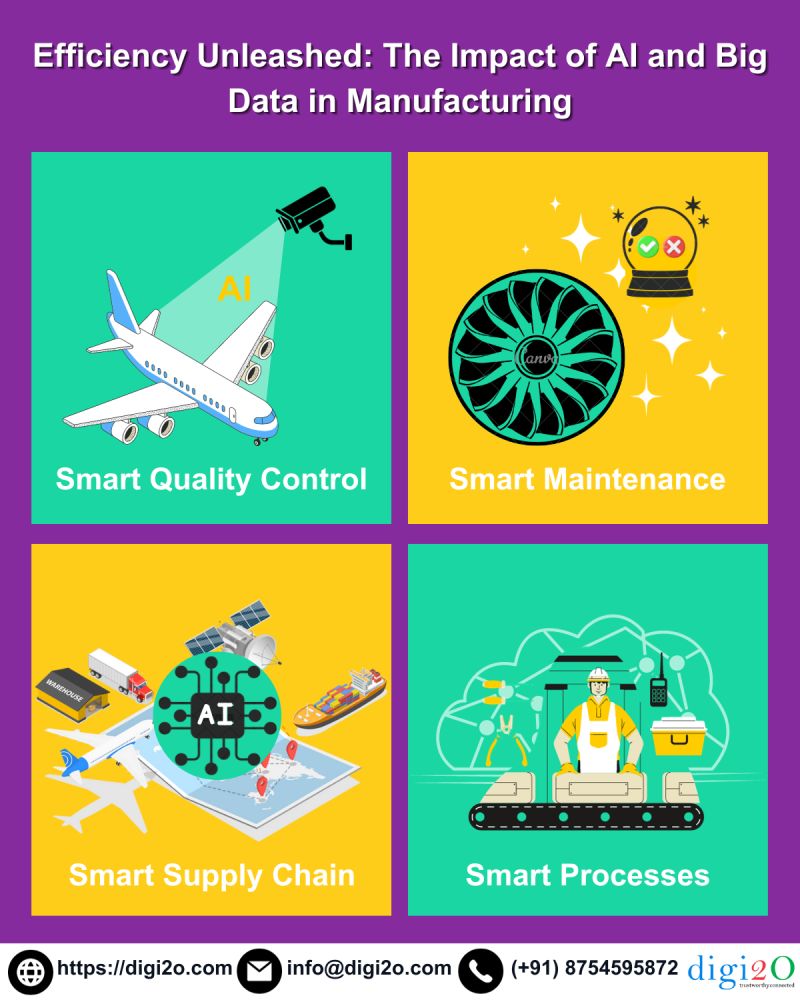

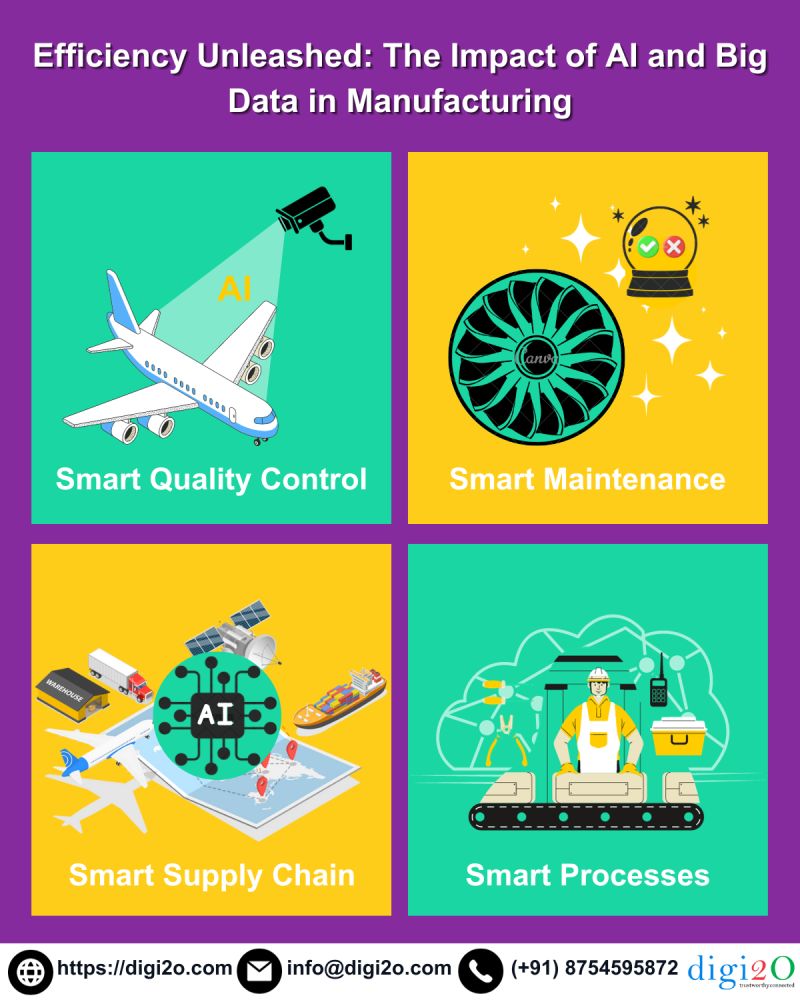

In the pulsating heart of every thriving factory, a symphony of machines, skilled workers, and intricate processes unfolds. Picture a scenario where this symphony is not just harmonious but also incredibly efficient, where every gear turns with meticulous precision, leaving no room for wastage or inefficiency. This vision is not a futuristic fantasy; it's the very essence of what artificial intelligence (AI) and big data analytics are crafting for the manufacturing industry. In the realm of process optimization, these technological marvels are not just rewriting the rules; they are transforming ordinary production lines into hubs of unparalleled productivity and efficiency.

Understanding the Dynamics: The Power of AI and Big Data Analytics

Artificial Intelligence (AI): At the core of this revolution lies the ingenuity of AI algorithms. These algorithms, akin to master conductors, delve deep into the ocean of data generated by sensors, machines, and various sources within a manufacturing unit. Their brilliance lies in deciphering intricate patterns, identifying trends, and pinpointing anomalies within this data tapestry. This analysis isn't mere number-crunching; it's the art of unlocking the latent potential within manufacturing processes. AI algorithms optimise parameters, predict potential failures, and empower decision-makers with invaluable insights, propelling production to unprecedented heights of efficiency and excellence.

Big Data Analytics: Working in perfect synergy with AI, big data analytics acts as the lifeblood, providing the necessary sustenance for AI algorithms to learn, adapt, and evolve. By offering a constant influx of data, big data analytics ensures that AI algorithms are not stagnant entities but dynamic, learning systems. This seamless collaboration between AI and big data analytics is akin to the perfect duet, propelling manufacturing towards levels of efficiency and productivity previously deemed unattainable.

A Real-World Triumph: The Siemens Factory, Amberg, Germany

The transformative power of AI and big data analytics isn't a theoretical concept; it's a tangible reality witnessed at the Siemens factory in Amberg, Germany. Here, AI takes centre stage, meticulously analysing data flowing from sensors on production lines. The insights gleaned from this analysis empower Siemens to optimise critical process parameters, such as machine speeds and feed rates.

The impact is staggering. Thanks to the implementation of AI, Siemens has achieved a remarkable 10% increase in production efficiency and a significant 5% reduction in scrap rates. This isn't merely a testament to efficiency; it's a resounding confirmation of the immense potential AI holds for the manufacturing sector. The sound of machinery working seamlessly is not just music to the ears; it's a testament to the transformative power of AI and big data analytics.

The Multifaceted Benefits: AI and Big Data Analytics in Manufacturing

1. Enhanced Efficiency:

AI and big data analytics optimise processes, foresee potential bottlenecks, and ensure every resource, whether time or materials, is maximised. Wastage is minimised, productivity soars, and efficiency becomes the cornerstone of operations.

2. Cost Reduction:

Efficiency isn't just about speed; it's about smart resource utilisation. By eliminating inefficiencies and reducing waste, operational costs plummet. Every penny saved directly contributes to enhancing the bottom line.

3. Superior Quality:

Predictive analytics, a gift from AI, ensures quality issues are identified and rectified proactively. This not only conserves resources but also upholds the brand's reputation, nurturing customer trust and loyalty.

4. Augmented Safety:

AI-driven predictive maintenance guarantees machinery operates optimally, reducing the risk of accidents. A safer workplace isn't just a legal requirement; it's a strategic imperative that protects the workforce, prevents costly downtime, and mitigates legal liabilities.

Embrace the Future: Navigating the World of AI and Big Data Solutions

For progressive manufacturers, the time to embrace AI and big data analytics is now. The market brims with visionary vendors and solution providers, eager to guide you on this transformative odyssey. Whether you are an industrial giant or a burgeoning enterprise, these technologies offer bespoke solutions tailored to your unique requirements.

The amalgamation of AI and big data analytics is not merely a technological advancement; it's a paradigm shift in the manufacturing landscape. The Siemens success story is not an isolated incident; it's a testament to how these technologies can elevate the mundane into the extraordinary, rewriting the narrative of what's possible in the realm of production and efficiency.

In the transformative landscape of Industry 4.0, the convergence of artificial intelligence (AI) and manufacturing has ushered in unprecedented advancements. However, amidst this wave of innovation, the spotlight intensifies on a critical facet - CYBERSECURITY.

AI-Enabled Innovation: The Driving Force

Industry 4.0 ushers us into an era of smart factories, where machines, sensors, and devices communicate seamlessly, optimizing processes and enhancing product quality. At the heart of this revolution lies AI, powered by big data and the Internet of Things (IoT). While these technological marvels promise efficiency, they also present significant challenges.

The Challenge: Protecting the Digital Thread

As our manufacturing processes intertwine with digital intricacies, safeguarding this digital thread becomes paramount. The challenges faced are diverse, ranging from data breaches to operational disruptions, posing a threat to both intellectual property and physical safety.

The Importance of Cybersecurity: Guarding our Innovation

Data Privacy: Safeguarding Intellectual Property

Our innovations hinge on data, making its protection critical. Robust encryption, stringent access controls, and regular audits form the cornerstone of our data privacy strategy. By fortifying our data, we ensure the sanctity of our intellectual property.

Preventing Disruptions: Ensuring Continuous Operations

Downtime in a smart factory can have crippling financial implications. Intrusion detection and response systems act as vigilant guards, minimizing the risk of operational interruptions. Rapid response to potential threats ensures seamless operations, preserving both productivity and profits.

Employee Training: Strengthening the Human Firewall

Our workforce is our first line of defense. Raising awareness and educating employees about cybersecurity best practices is indispensable. Through continuous training, we empower our team to recognize and thwart potential threats effectively.

Regulatory Compliance: Upholding Industry Standards

Navigating the intricate web of industry regulations is non-negotiable. Staying abreast of these regulations not only ensures legal compliance but also reaffirms our commitment to data security. By adhering to industry standards, we create a robust framework for cybersecurity.

Collaboration is Key: Uniting for a Secure Future

In the dynamic landscape of Industry 4.0, collaboration emerges as our strongest ally. Manufacturers, researchers, and government agencies must join forces, sharing insights and best practices. This collaborative spirit elevates the entire industry, fostering an environment of mutual growth and security.

As we stride further into the realm of AI-enabled manufacturing, cybersecurity ceases to be an option; it becomes a necessity. It falls upon us, as a collective, to protect our digital future, ensuring a safe and secure environment for businesses and employees alike.

Let Us Fortify Our Defenses Against Cyber Threats

In Industry 4.0, our interconnectedness is our strength. Let us connect, discuss, and fortify our defenses against cyber threats. Together, we can shape a safer, more resilient future for manufacturing.

#Industry4.0# AI #Cybersecurity #Innovation #Manufacturing #SecurityMatters

Designed by W3Squad