In the fast-paced world of manufacturing, every second counts. The last thing you need is a sudden breakdown disrupting your operations. But fear not! The magic of IoT (Internet of Things) is here to save the day. Let's embark on a journey to seamlessly integrate IoT devices into your industrial processes and revolutionize your production line!

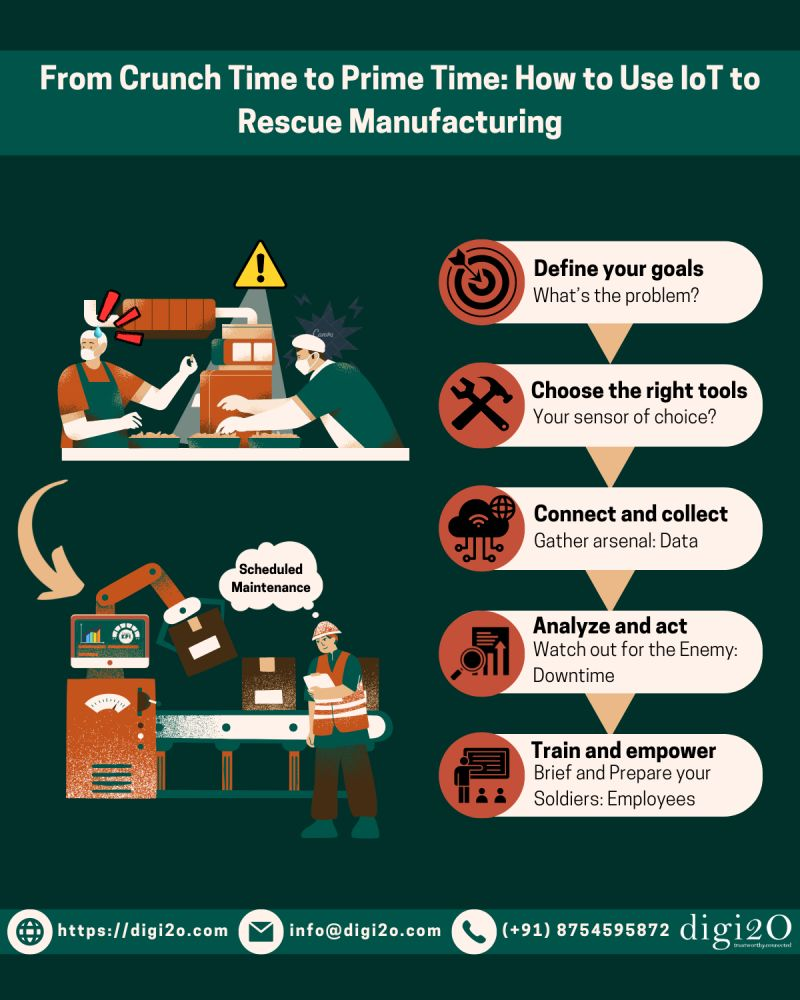

Defining Your Goals

Before diving into the world of IoT, it's crucial to define your objectives. What challenges are you facing in your manufacturing process? Are you struggling with machine downtime, inefficient inventory management, or unpredictable maintenance costs? By clearly identifying your goals, you can tailor your IoT implementation to address specific pain points.

Key Point: Define clear objectives to guide your IoT integration process.

Choosing the Right Tools

With a plethora of IoT devices available in the market, selecting the right tools can be daunting. From sensors to gateways, each component plays a crucial role in capturing and transmitting data. Consider factors such as compatibility, reliability, and scalability when choosing your IoT infrastructure.

Key Point: Research and select IoT devices that align with your requirements and budget.

Connecting and Collecting

Once you've chosen your IoT devices, it's time to connect them to your existing network and start collecting data. Whether through Wi-Fi, Bluetooth, or cellular connectivity, ensure seamless communication between devices. Establish robust data collection mechanisms to gather insights in real-time.

Key Point: Establish a secure and reliable network for seamless data collection from IoT devices.

Analyzing and Acting

Data without analysis is like a puzzle without solving. Leverage advanced analytics tools to process the data collected from your IoT devices. Identify patterns, detect anomalies, and derive actionable insights to optimize your manufacturing processes. From predictive maintenance to demand forecasting, data-driven decisions can drive efficiency and profitability.

Key Point: Utilize analytics tools to transform raw data into actionable insights for informed decision-making.

Training and Empowering

Empower your workforce to embrace the IoT revolution through comprehensive training programs. Educate employees on the benefits of IoT integration and provide hands-on experience with IoT devices. Foster a culture of innovation and continuous learning to ensure smooth adoption and utilization of IoT technologies.

Key Point: Invest in training to equip your team with the skills and knowledge needed for successful IoT implementation.

Real-time Insights: The Power of IoT

IoT enables real-time monitoring of machine health, inventory levels, and production metrics. With instant access to critical data, manufacturers can make proactive decisions to optimize efficiency and minimize downtime. Imagine having eyes everywhere in your factory, ensuring smooth operations round the clock.

Predictive Maintenance Made Easy

Gone are the days of reactive maintenance. IoT empowers manufacturers to anticipate equipment failures before they occur. By analyzing sensor data for early warning signs, predictive maintenance schedules can be implemented, reducing costly downtime and extending asset lifespan.

Smarter Supply Chains with IoT

IoT revolutionizes inventory management by providing real-time visibility into stock levels and consumption patterns. Automated replenishment systems ensure that essential parts are always available when needed, minimizing production delays and excess inventory costs.

Enhancing Efficiency with IoT

From streamlining production workflows to optimizing energy usage, IoT offers endless possibilities for enhancing efficiency in manufacturing. By leveraging data-driven insights, manufacturers can identify bottlenecks, eliminate waste, and continuously improve processes for maximum productivity.

Overcoming Challenges

Despite its numerous benefits, IoT integration comes with its own set of challenges. From cybersecurity threats to interoperability issues, manufacturers must navigate various obstacles to ensure successful implementation. However, with careful planning and strategic investments, these challenges can be overcome, unlocking the full potential of IoT in industrial processes.

In today's fast-paced world, keeping up with the demands of supply chain management (SCM) can be a daunting task. However, with the integration of IoT (Internet of Things), businesses can revolutionize their operations, gaining insights and efficiencies like never before. Let's delve into how IoT can transform SCM and unlock its full potential.

Real-time Visibility

What is real-time visibility?

Real-time visibility in SCM refers to the ability to track inventory movements instantly, from raw materials to finished products. It's akin to having a GPS tracker on every item in your supply chain, allowing you to monitor their locations and statuses continuously.

How does IoT enable real-time visibility?

IoT sensors placed on goods, equipment, and vehicles collect data and transmit it in real time to a central system. This data provides insights into inventory levels, delivery statuses, and potential bottlenecks, empowering businesses to make informed decisions swiftly.

Why is real-time visibility important?

Having real-time visibility enhances agility and responsiveness in SCM. It helps minimize stockouts, reduce excess inventory, and optimize resource allocation, ultimately leading to improved customer satisfaction and cost savings.

Predictive Maintenance

What is predictive maintenance?

Predictive maintenance involves using data analytics to predict equipment failures before they occur. It's like having a crystal ball that forewarns you of potential breakdowns, allowing proactive maintenance to prevent disruptions in operations.

How does IoT facilitate predictive maintenance?

IoT sensors installed on machinery continuously monitor various parameters such as temperature, vibration, and performance metrics. By analyzing this data using machine learning algorithms, patterns indicative of potential failures can be detected, enabling timely intervention.

What are the benefits of predictive maintenance?

Predictive maintenance minimizes downtime, reduces maintenance costs, and prolongs the lifespan of equipment. It shifts maintenance activities from reactive to proactive, ensuring optimal equipment performance and uninterrupted production processes.

Improved Efficiency

How does IoT enhance efficiency in SCM?

IoT optimizes various aspects of the supply chain, including inventory management, logistics, and transportation. By automating repetitive tasks, providing real-time insights, and enabling predictive analytics, IoT streamlines operations and eliminates inefficiencies.

What are some examples of IoT-driven efficiency improvements?

IoT enables route optimization for delivery vehicles, ensuring timely deliveries while minimizing fuel consumption and vehicle wear and tear. It also facilitates automated inventory replenishment based on demand forecasts, preventing stockouts and overstock situations.

Technologies Used in IoT

What technologies are utilized in IoT for SCM?

IoT solutions for SCM incorporate a range of technologies such as sensors, RFID (Radio Frequency Identification), GPS (Global Positioning System), and cloud computing. These technologies work in tandem to collect, transmit, and analyze data, enabling intelligent decision-making.

Sensors in SCM

How do sensors contribute to SCM optimization?

Sensors play a pivotal role in capturing real-time data throughout the supply chain. Whether it's monitoring temperature-sensitive goods during transit or tracking the utilization of warehouse space, sensors provide granular insights that drive operational efficiencies.

Applications of IoT

What are some practical applications of IoT in SCM?

IoT finds applications across various SCM processes, including inventory management, demand forecasting, supplier relationship management, and order fulfillment. For instance, RFID tags enable automated inventory tracking, while predictive analytics enhance demand planning accuracy.

Challenges

What are the challenges associated with implementing IoT in SCM?

Challenges include data security concerns, interoperability issues among IoT devices and systems, high initial investment costs, and the need for skilled personnel to manage and interpret IoT-generated data.

Benefits

What are the key benefits of adopting IoT in SCM?

Benefits include enhanced visibility and transparency across the supply chain, improved operational efficiency, reduced costs through optimized resource utilization, and the ability to offer superior customer service through faster order fulfillment and delivery.

Economic Implications

How does IoT integration impact the economy?

IoT integration in SCM leads to economic benefits such as increased productivity, job creation in technology-related sectors, and improved competitiveness for businesses through enhanced operational efficiencies and customer satisfaction.

Getting Started with IoT

How can businesses begin implementing IoT in their supply chain?

Businesses can start by identifying areas within their supply chain where IoT can provide the most significant value, such as inventory management, logistics optimization, or predictive maintenance. They should then invest in reliable IoT infrastructure, collaborate with technology partners, and train their workforce to leverage IoT capabilities effectively.

Conclusion

In conclusion, IoT integration holds immense potential for optimizing supply chain management, offering real-time visibility, predictive insights, and enhanced efficiency. By embracing IoT technologies and overcoming associated challenges, businesses can transform their supply chain operations, gaining a competitive edge in today's dynamic marketplace.

Before delving into the integration process, let's grasp the essence of IoT. Imagine a vast network of interconnected devices – from sensors and machines to vehicles and appliances – all communicating seamlessly to collect and exchange data. This interconnectedness forms the foundation of IoT, revolutionizing how industries operate.

Industry 4.0 represents the fourth industrial revolution, characterized by the fusion of digital technologies with traditional manufacturing processes. It heralds a new era of automation, data exchange, and smart technology integration, paving the way for enhanced efficiency and productivity.

Before integration begins, it's crucial to identify the specific areas within industrial processes where IoT can make a significant impact. Whether it's optimizing supply chain management, enhancing predictive maintenance, or improving product quality, pinpointing these opportunities is the first step toward successful implementation.

With a plethora of IoT devices and sensors available in the market, choosing the right ones can be daunting. Consider factors such as compatibility, functionality, scalability, and security when selecting devices tailored to your industrial needs. Remember, each device serves as a building block in the IoT ecosystem, contributing to the overarching efficiency of your operations.

Once the devices are selected, the next step is to establish robust connectivity and network infrastructure. Whether utilizing Wi-Fi, Bluetooth, RFID, or cellular networks, ensuring seamless communication between devices and the centralized system is imperative. Additionally, incorporating edge computing capabilities can minimize latency and enhance real-time data processing at the source.

IoT platforms and analytics tools play a pivotal role in harnessing the potential of data generated by IoT devices. These platforms facilitate data aggregation, visualization, and analysis, empowering businesses to derive actionable insights and make informed decisions. Whether deploying cloud-based solutions or on-premises systems, choosing the right platform tailored to your requirements is essential.

As data becomes the lifeblood of IoT-driven industrial processes, safeguarding it against cyber threats and breaches is paramount. Implement robust encryption protocols, access controls, and intrusion detection systems to fortify your IoT ecosystem. Additionally, adhere to data privacy regulations such as GDPR to maintain transparency and trust with stakeholders.

Deploying and integrating IoT devices into existing industrial infrastructure requires meticulous planning and execution. Adopt agile methodologies and collaborate closely with cross-functional teams to streamline the deployment process. Conduct thorough testing and validation to identify and rectify any compatibility issues or operational bottlenecks before full-scale implementation.

Once the IoT ecosystem is operational, continuous monitoring and maintenance are essential to ensure optimal performance and reliability. Implement proactive maintenance strategies leveraging predictive analytics to detect potential failures before they occur. Additionally, establish robust incident response protocols to address any unforeseen issues promptly.

Beyond operational enhancements, the true value of IoT lies in its ability to drive transformative business outcomes. Leverage the insights from IoT data to optimize processes, innovate product offerings, and enhance customer experiences. By harnessing the power of data-driven decision-making, businesses can stay ahead of the curve in today's competitive landscape.

In conclusion, integrating IoT devices into industrial processes is not just a technological endeavor but a strategic imperative in the era of Industry 4.0. By following these step-by-step guidelines, businesses can unlock new levels of efficiency, productivity, and innovation, driving sustainable growth and competitive advantage in the digital age.

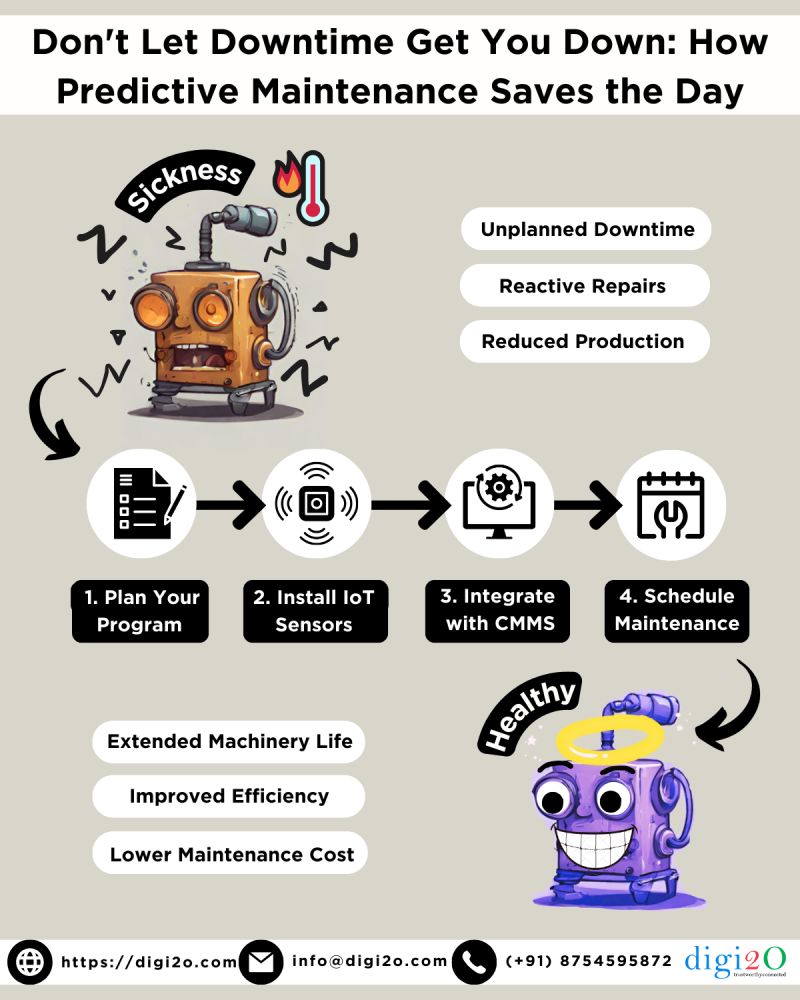

In the dynamic realm of manufacturing, efficiency is paramount. A single glitch in the production line can cascade into significant downtime, wreaking havoc on schedules and profitability. Traditional maintenance practices, reliant on fixed schedules or reactive responses, are no longer sufficient to meet the demands of modern manufacturing. Here's where predictive maintenance (PdM) emerges as a game-changer, ushering in a new era of proactive and streamlined operations.

Unplanned downtime is the bane of manufacturing existence, causing disruptions that ripple through the entire supply chain. Beyond the direct financial implications, such as lost production and idle manpower, the intangible costs of damaged reputation and diminished customer confidence loom large. Outdated maintenance strategies, marked by a lack of foresight and reliance on manual interventions, exacerbate these challenges. Reactive repairs, often prompted by catastrophic failures, not only inflate maintenance expenditure but also compromise operational efficiency.

Enter predictive maintenance, a proactive approach empowered by IoT sensors and AI-driven analytics. Unlike traditional methods, PdM doesn't merely react to equipment malfunctions; it anticipates them, leveraging real-time data insights to forestall potential breakdowns. By harnessing a myriad of metrics, from vibration patterns to temperature fluctuations, PdM transforms equipment health monitoring into a predictive science.

The adoption of predictive maintenance yields a plethora of advantages, amplifying the operational prowess of manufacturing facilities:

By detecting anomalies in equipment performance at their nascent stages, PdM empowers manufacturers to intervene proactively, averting full-scale breakdowns. Consequently, unplanned downtime is minimized, ensuring uninterrupted production schedules and enhanced customer satisfaction.

The shift from reactive to proactive maintenance translates into substantial cost savings. Investments in predictive analytics and IoT infrastructure pale in comparison to the exorbitant expenses incurred during emergency repairs. Moreover, predictive maintenance optimizes resource allocation, ensuring that maintenance activities are targeted and efficient.

PdM optimizes equipment performance by identifying and rectifying inefficiencies before they escalate. By streamlining maintenance schedules and prioritizing interventions based on data-driven insights, manufacturers can unlock newfound levels of productivity and operational agility.

Early detection of potential malfunctions allows for timely interventions, thereby extending the lifespan of critical assets. By addressing issues preemptively, manufacturers can mitigate wear and tear, preserving the integrity of machinery and deferring costly replacements.

In the realm of food and beverage production, where precision is paramount and downtime is intolerable, the integration of predictive maintenance has yielded remarkable results. Consider a chocolate factory, where the seamless operation of churners and conveyors is non-negotiable. By deploying IoT sensors to monitor equipment health and leveraging AI algorithms to anticipate maintenance needs, manufacturers can ensure the uninterrupted flow of production, safeguarding both quality and efficiency.

The transition to predictive maintenance necessitates a strategic approach, encompassing meticulous planning and seamless execution:

Begin by identifying the key areas of focus for predictive maintenance implementation. Analyze historical maintenance data to pinpoint recurring issues and prioritize equipment assets based on criticality and operational impact.

Equip your machinery with a comprehensive array of IoT sensors capable of capturing relevant performance metrics. From temperature sensors to acoustic monitors, ensure that your sensor network is tailored to the unique requirements of your manufacturing environment.

Centralize and analyze the deluge of data generated by IoT sensors through a robust Computerized Maintenance Management System (CMMS). Leverage AI-powered analytics tools to derive actionable insights and facilitate data-driven decision-making.

Leverage predictive insights to overhaul traditional maintenance schedules, transitioning from reactive to proactive interventions. Implement predictive maintenance routines based on equipment health forecasts, optimizing resource allocation and minimizing downtime.

In conclusion, the adoption of predictive maintenance heralds a paradigm shift in manufacturing operations, empowering organizations to transcend the limitations of traditional maintenance practices. By harnessing the power of IoT sensors and AI-driven analytics, manufacturers can transform reactive firefighting into proactive problem-solving, paving the way for enhanced efficiency, productivity, and competitiveness.

Ready to embark on your predictive maintenance journey? Embrace the future of manufacturing today!

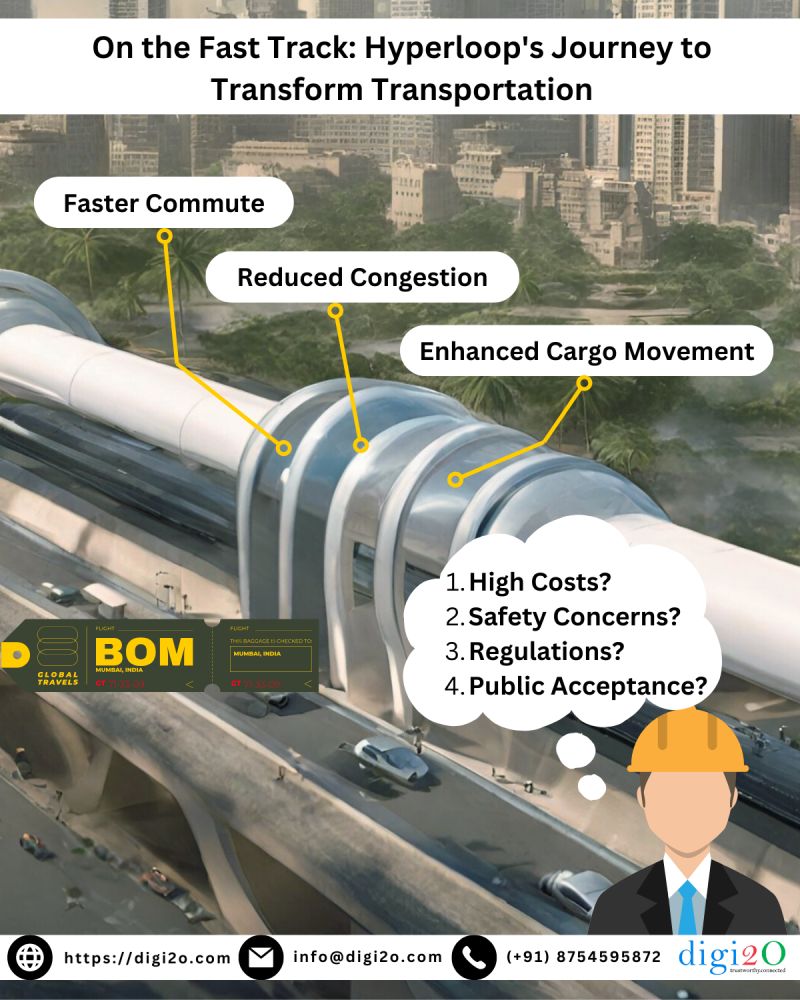

In recent years, the concept of the Hyperloop has captured the imagination of people worldwide. Promising unprecedented speed and efficiency in transportation, this revolutionary technology, championed by companies like Virgin Hyperloop, has sparked both excitement and skepticism. In this article, we delve deep into the potential of Hyperloop, exploring its bold vision, feasibility, challenges, and the future of transportation.

Virgin Hyperloop's Bold Vision🚀

Virgin Hyperloop envisions a future where travel is transformed, offering faster commutes, reduced congestion, and enhanced cargo movement. The prospect of commuting from Mumbai to Pune in just 28 minutes is indeed tantalizing. Imagine the implications for urban planning and development – with travel times drastically reduced, cities could expand further, allowing people to live in smaller towns while easily commuting to major urban hubs. This could lead to a renaissance in urban design, reshaping how we perceive and plan our cities.

Moreover, Hyperloop has the potential to alleviate traffic congestion, particularly in densely populated urban areas. By providing an alternative mode of transportation, Hyperloop could reduce the number of cars on the road, leading to cleaner air, less noise pollution, and potentially improved public health outcomes. Additionally, Virgin Hyperloop's focus on cargo transportation holds promise for streamlining supply chains, reducing truck traffic, and ultimately lowering transportation costs for businesses and consumers alike.

Feasibility and Challenges🧗🏼♀️

Despite its promising vision, the Hyperloop concept faces several challenges that must be addressed for widespread adoption. Chief among these challenges is the high infrastructure costs associated with building and maintaining a network of Hyperloop tubes. The significant investment required may pose financial hurdles, impacting the feasibility of implementing Hyperloop technology on a large scale.

Safety is another paramount concern. Operating at near-sonic speeds within a sealed environment presents unique safety challenges that must be addressed comprehensively. Ensuring the safety of passengers and cargo is paramount to the success and public acceptance of Hyperloop technology.

Furthermore, regulatory hurdles and public acceptance pose additional challenges. Introducing a new mode of transportation requires navigating complex regulatory frameworks and gaining public trust. Building consensus among stakeholders and addressing concerns about safety, environmental impact, and accessibility will be crucial for the widespread adoption of Hyperloop technology.

The Future of Hyperloop💫

Despite the challenges, Virgin Hyperloop's pilot projects with airports and ports are promising steps towards testing the feasibility and gathering real-world data. These pilot projects will provide valuable insights into the practicality, safety, and efficiency of Hyperloop technology in various environments.

Looking ahead, Hyperloop has the potential to revolutionize transportation on a global scale. By offering unprecedented speed, efficiency, and sustainability, Hyperloop could reshape how we live, work, and connect. As technology continues to evolve and innovators push the boundaries of what's possible, Hyperloop represents a glimpse into the future of transportation.

Join the conversation🗨️

What are your thoughts on Hyperloop? Do you believe it has the potential to revolutionize transportation as we know it? Share your insights in the comments below!

If you want to read more information about how to boost traffic on your Website, just visit The Insider's Views.

Designed by W3Squad