Change. - It's a four-letter word that can send shivers down the spines of even the most progressive companies. Especially when it comes to the massive shift of Industry 4.0. But fear not, fellow leaders! This post offers a powerful toolkit to slay the dragon of resistance: ⚔️Overcoming Resistance to Change.

Let’s face it, we’ve all been there. Employees cling to old habits, uncertainty breeds fear, and the comfort zone beckons. Sound familiar?????????

Change is often met with resistance due to psychological and organizational factors. To effectively address this resistance, it’s crucial to understand its root causes:

People often fear what they do not understand. The transition to Industry 4.0 involves new technologies, processes, and workflows. This unfamiliar territory can be intimidating, leading to a resistance to change.

Employees may feel that they are losing control over their work and environment. The structured, predictable routines they are accustomed to are disrupted, making them feel insecure and anxious.

A lack of trust in leadership can exacerbate resistance. If employees do not believe that the transformation is in their best interest or that leadership is capable of guiding them through the change, they are more likely to resist.

Change pushes people out of their comfort zones. The routines and methods that employees have relied on for years are suddenly under threat, causing discomfort and resistance.

Poor communication about the transformation process, its benefits, and its implications can fuel uncertainty and fear. Employees need clear, transparent communication to feel confident about the change.

To overcome resistance, empower employees who embrace change. These individuals can be turned into vocal advocates for the exciting future ahead. Here’s how to create your own team of Change Ninjas:

Look for employees who are naturally enthusiastic about new technologies and processes. These early adopters can help spread positive attitudes toward change.

Provide these change advocates with the tools and information they need to understand and promote the transformation. Equip them with the necessary training and resources to lead by example.

Encourage your Change Ninjas to share their experiences and successes with their peers. This peer-to-peer influence can be more effective than top-down directives in building support for the transformation.

Crafting a compelling vision of the future is essential for overcoming resistance. This vision should highlight the benefits of Industry 4.0 for both the company and its employees.

Clearly articulate how the transformation will benefit the organization and its people. Emphasize the opportunities for growth, innovation, and increased efficiency.

Use storytelling techniques to make the vision relatable and inspiring. Share success stories from other organizations that have successfully navigated similar transformations.

Create visual representations of the future state of the organization. This can include infographics, videos, or interactive presentations that showcase the benefits of the transformation.

Involving employees in the transformation process from the beginning fosters a sense of ownership and builds trust.

Hold open forums where employees can voice their concerns, ask questions, and provide input. This inclusive approach helps to alleviate fears and build confidence in the transformation.

Actively seek and incorporate employee feedback into the transformation strategy. This demonstrates that leadership values their input and is committed to addressing their concerns.

Regularly share updates on the progress of the transformation. This transparency helps to keep employees informed and engaged in the process.

A key aspect of overcoming resistance is ensuring that employees have the skills and knowledge to thrive in the new digital landscape.

Conduct a thorough assessment of the skills required for the transformation and identify any gaps in the current workforce. This assessment will help to tailor training programs to meet the needs of employees.

Create training programs that are comprehensive and accessible. These programs should cover both technical skills and soft skills, such as adaptability and problem-solving.

Offer ongoing support and resources to help employees continue their learning journey. This can include access to online courses, workshops, and mentorship opportunities.

Effective communication is crucial for building support and addressing resistance. Use multiple channels and methods to keep everyone informed.

Utilize a variety of communication channels to reach all employees. This can include emails, intranet posts, webinars, and face-to-face meetings.

Tailor communication messages to address the specific concerns and needs of different groups within the organization. Personalized communication can be more effective in building support for the transformation.

Encourage open dialogue and provide opportunities for employees to ask questions and share their concerns. This helps to build trust and confidence in the transformation process.

Recognizing and celebrating achievements along the way can help to maintain momentum and build enthusiasm for the transformation.

Acknowledge and celebrate both individual and team achievements. This recognition can boost morale and reinforce positive attitudes toward the change.

Share success stories from different parts of the organization to highlight the benefits of the transformation. This can help to inspire and motivate others to embrace the change.

Consider implementing reward programs to recognize and reward employees who make significant contributions to the transformation. This can include bonuses, promotions, or other forms of recognition.

A culture of continuous learning is vital for adapting to the changes brought about by Industry 4.0.

Encourage employees to explore new technologies and methods on their own. This self-directed learning can help to build confidence and adaptability.

Create an environment where experimentation is encouraged and failure is seen as a learning opportunity. This can help employees to develop a growth mindset and become more open to change.

Provide access to a variety of learning resources, such as online courses, books, and workshops. This can help employees to continuously develop their skills and knowledge.

Leadership behavior sets the tone for the entire organization. Leaders must demonstrate the behaviors and attitudes they want to see in their employees.

Show enthusiasm for the transformation and the opportunities it presents. This enthusiasm can be contagious and help to build excitement among employees.

Be willing to adapt and change your own behavior in response to the transformation. This demonstrates a commitment to the change and sets a positive example for others.

Communicate openly and honestly about the transformation process, including any challenges and setbacks. This transparency helps to build trust and credibility.

Leveraging technology effectively can make the transition to Industry 4.0 smoother and more efficient.

Use digital tools to facilitate collaboration, streamline processes, and improve communication. This can include project management software, communication platforms, and data analytics tools.

Identify and automate repetitive tasks to free up time for more strategic activities. This can help to increase efficiency and reduce resistance to change.

Use data analytics to inform decision-making and track the progress of the transformation. This can help to identify areas for improvement and make adjustments as needed.

Change is a constant. Continuously monitor progress, gather feedback, and be willing to adjust your strategies for optimal results.

Regularly monitor the progress of the transformation and assess its impact on the organization. This can help to identify any issues or areas for improvement.

Actively seek feedback from employees and other stakeholders to understand their experiences and concerns. This feedback can inform future strategies and help to address any resistance.

Be willing to adjust your strategies and approaches based on feedback and changing circumstances. This flexibility can help to ensure the success of the transformation.

Resistance to change is a hurdle, not a roadblock. By understanding the reasons behind this resistance and adopting these actionable strategies, you can transform resistance into a springboard for growth. Empower your employees, paint a compelling vision, embrace transparency, and prioritize learning to unlock the limitless possibilities of Industry 4.0.????

Let's ditch the fear and embrace the future together! ????

Is your manufacturing business stuck in a mindset maze? ???? Innovation is crucial for thriving in today's competitive manufacturing landscape. Yet, certain mental roadblocks can impede the adoption of new technologies and ideas, leaving your company lagging behind. In this article, we’ll explore four sneaky mindsets that can hinder innovation adoption in manufacturing and provide actionable strategies to overcome them. Ready to dive in?

The fixed mindset is the belief that intelligence and abilities are static and unchangeable. This mentality fosters a fear of failure and a resistance to change. In the context of manufacturing, a fixed mindset can be detrimental, leading to missed opportunities for improvement and innovation.

NIH Syndrome occurs when a company or team prioritizes internal ideas over external inspiration. This mindset can limit innovation by isolating the organization from beneficial outside insights and solutions.

Analysis paralysis refers to the state of overanalyzing or overthinking a situation so that a decision or action is never taken. In manufacturing, this can delay projects and hinder innovation adoption.

The fear of cannibalization is the apprehension that new products or innovations will detract from existing ones. This mindset can stifle innovation as companies might avoid new ventures that could disrupt their current offerings.

Employees and managers alike may fall into the comfort zone trap, where the familiarity of existing processes and technologies discourages them from exploring new avenues.

A resource scarcity mindset focuses on perceived limitations in budget, time, or personnel, often leading to an overly conservative approach to innovation.

Many manufacturing companies are attached to legacy systems that are familiar but outdated, hindering the adoption of new technologies.

A rigid hierarchical structure can suppress innovation by limiting the flow of ideas and slowing down decision-making processes.

A short-term focus emphasizes immediate results over long-term innovation, leading to a lack of sustained growth and development.

The consensus bias involves seeking unanimous agreement before making decisions, which can slow down innovation and discourage bold ideas.

Overcoming these four sneaky mindsets—fixed mindset, Not Invented Here Syndrome, analysis paralysis, and fear of cannibalization—is crucial for fostering innovation in manufacturing. By promoting a growth mindset, seeking external inspiration, focusing on experimentation, and welcoming disruption, your organization can break free from these roadblocks and unlock its full potential.

Innovation is not just about technology; it's about changing how we think and act. By addressing these mindsets, manufacturing businesses can create a culture of continuous improvement and stay competitive in an ever-evolving landscape. Ready to embrace innovation? Let's start by challenging our own assumptions and

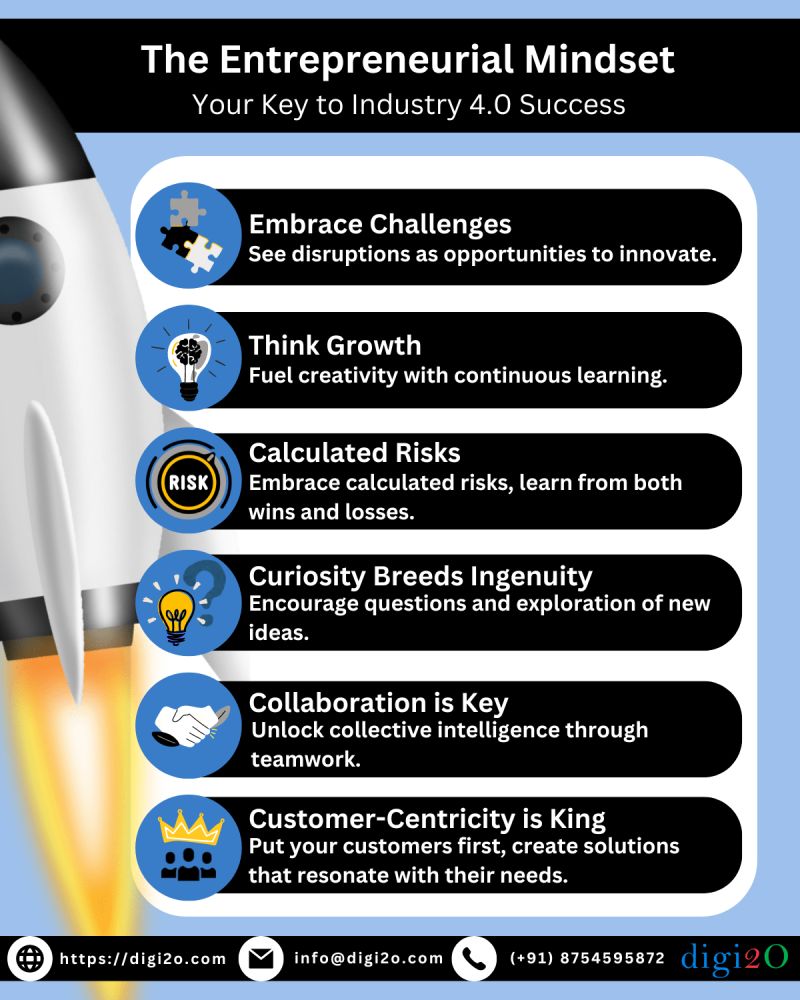

In today’s rapidly evolving business landscape, characterized by the convergence of advanced technologies and digital transformation, staying ahead of the curve is more critical than ever. Industry 4.0, or the Fourth Industrial Revolution, is reshaping industries by integrating cyber-physical systems, the Internet of Things (IoT), artificial intelligence (AI), and cloud computing. To navigate and thrive in this complex environment, businesses need more than just technological prowess; they need an entrepreneurial mindset.

The entrepreneurial mindset is a way of thinking that enables individuals and organizations to see opportunities where others see obstacles. It involves a relentless pursuit of innovation, a willingness to take calculated risks, and a continuous drive for growth and improvement. This mindset is crucial for businesses looking to capitalize on the opportunities presented by Industry 4.0.

Before delving into how the entrepreneurial mindset intersects with Industry 4.0, it’s essential to understand the core components of this industrial revolution:

These technologies are transforming industries, but to harness their full potential, businesses must adopt an entrepreneurial mindset.

One of the hallmarks of the entrepreneurial mindset is viewing challenges not as barriers but as opportunities. In the context of Industry 4.0, this means embracing technological disruptions as a chance to innovate. Digital transformation often brings about significant changes in how businesses operate, but those who adapt quickly can leverage these changes to their advantage.

For instance, during the COVID-19 pandemic, many companies faced unprecedented operational challenges. Those with an entrepreneurial approach pivoted swiftly, adopting remote work technologies and enhancing their digital capabilities. As a result, they not only survived but thrived, discovering new avenues for growth.

Tesla, a pioneer in the electric vehicle market, exemplifies how embracing challenges can lead to innovation. Faced with production bottlenecks and supply chain disruptions, Tesla implemented agile manufacturing processes and rapidly iterated its production techniques. This flexibility enabled Tesla to scale production and maintain a competitive edge.

Continuous learning and development are at the core of the entrepreneurial mindset. In Industry 4.0, where technology and market conditions are constantly evolving, a commitment to growth is essential. This involves fostering a culture where learning is encouraged and supported at all levels of the organization.

To stay competitive, businesses must invest in upskilling and reskilling their workforce. This not only enhances employees’ capabilities but also drives organizational innovation. For example, companies like Amazon have launched extensive training programs to equip their employees with the skills needed for advanced technology roles, ensuring they stay ahead in the digital age.

Encouraging a growth mindset involves creating an environment where employees feel safe to experiment and learn from their failures. Companies like Google and Microsoft have adopted this approach, promoting a culture where innovation is nurtured through continuous learning and exploration.

Risk-taking is a fundamental aspect of the entrepreneurial mindset. However, in the context of Industry 4.0, it’s about taking calculated risks. This means analyzing potential opportunities and threats, making informed decisions, and being prepared to pivot if necessary.

Effective risk management involves assessing the potential impact of new technologies and business models. For instance, companies venturing into the use of AI for predictive maintenance in manufacturing must evaluate the cost, implementation challenges, and potential ROI. By thoroughly understanding these factors, businesses can make decisions that balance risk and reward.

In innovative cultures, failure is seen as a step towards success. Celebrating failures and learning from them can lead to significant breakthroughs. For example, Dyson's journey to creating the first bagless vacuum cleaner involved over 5,000 prototypes. Each failed attempt provided valuable insights that eventually led to a market-leading product.

Entrepreneurs are inherently curious. They constantly question the status quo and seek new ways to solve problems. In the era of Industry 4.0, this curiosity drives ingenuity and innovation.

Organizations should foster an environment where curiosity is encouraged. This can be achieved by promoting open communication, providing access to diverse information sources, and supporting exploratory projects. When employees are encouraged to ask questions and challenge existing processes, they are more likely to develop innovative solutions.

Innovation often occurs at the intersection of different disciplines. Companies like IBM and Siemens are known for their interdisciplinary approach to research and development. By combining expertise from various fields, they push the boundaries of what’s possible, leading to groundbreaking innovations in areas like AI and smart manufacturing.

No great idea thrives in isolation. Collaboration is a critical element of the entrepreneurial mindset and is particularly important in Industry 4.0, where complex problems often require diverse perspectives and expertise.

Successful innovation requires teams that are diverse in their skills, backgrounds, and perspectives. Companies that promote cross-functional collaboration are better positioned to solve complex challenges. For example, Apple’s success can be attributed to its collaborative culture that brings together designers, engineers, and marketers to create products that are not only technologically advanced but also user-friendly.

Collaboration isn’t limited to internal teams. Forming strategic partnerships with other organizations can also drive innovation. By collaborating with startups, academic institutions, and technology providers, businesses can access new ideas and technologies. For instance, BMW's partnership with tech firms and universities has accelerated its development of autonomous driving technologies.

At the heart of the entrepreneurial mindset is a focus on customer-centricity. Understanding and meeting the needs of customers is crucial for success in Industry 4.0.

Entrepreneurs understand that customers are the ultimate arbiters of value. In Industry 4.0, businesses must prioritize customer feedback and adapt their offerings to meet evolving demands. For instance, Netflix’s data-driven approach to understanding viewer preferences has enabled it to tailor its content offerings, leading to high customer satisfaction and retention.

Customization and personalization are becoming increasingly important. Industry 4.0 technologies enable businesses to create bespoke solutions that cater to individual customer needs. Companies like Nike have embraced this by offering personalized products through their Nike By You platform, allowing customers to design their own footwear.

Technology is at the core of Industry 4.0, but it’s the entrepreneurial mindset that determines how effectively it’s leveraged. Businesses that combine technological capabilities with an entrepreneurial approach are best positioned to gain a competitive advantage.

Effective digital transformation requires a clear strategy aligned with business goals. This involves identifying the technologies that will drive the most significant impact and investing in their implementation. Companies like GE have transformed their operations by integrating IoT and big data analytics into their industrial processes, enhancing efficiency and creating new revenue streams.

Agile methodologies, which emphasize iterative development and flexibility, are essential for adapting to the rapid changes of Industry 4.0. Businesses that adopt agile practices are better equipped to respond to market demands and technological advancements. Spotify’s success in the competitive music streaming industry is partly due to its agile approach, which allows it to quickly iterate and improve its platform based on user feedback.

Leadership plays a crucial role in nurturing an entrepreneurial mindset within organizations. Leaders who embody entrepreneurial qualities inspire their teams to innovate and take risks.

Leaders who demonstrate curiosity, resilience, and a willingness to take risks set the tone for their organizations. For example, Elon Musk’s visionary leadership at SpaceX has fostered a culture of innovation and risk-taking, leading to groundbreaking achievements in space exploration.

Empowering employees to make decisions and take ownership of their work is vital. This can be achieved by providing autonomy, resources, and support. Companies like Zappos are known for their employee empowerment initiatives, which have led to high levels of innovation and customer satisfaction.

Despite the clear benefits of the entrepreneurial mindset, many organizations face barriers to fostering this culture. Common challenges include resistance to change, lack of resources, and a fear of failure.

Change can be daunting, especially in established organizations. Overcoming resistance requires clear communication about the benefits of innovation and involving employees in the transformation process. Toyota’s continuous improvement culture, known as Kaizen,

encourages employees at all levels to contribute ideas for innovation, helping to overcome resistance and drive sustained improvement.

Innovation often requires significant investment in terms of time, money, and effort. Organizations must prioritize and allocate resources effectively to support their innovation initiatives. Companies like 3M dedicate a portion of their budget to research and development, enabling them to consistently bring new products to market.

In the age of Industry 4.0, the entrepreneurial mindset is more than just a competitive advantage—it’s a necessity. By embracing challenges, fostering continuous learning, taking calculated risks, encouraging curiosity, promoting collaboration, and maintaining a customer-centric approach, businesses can navigate the complexities of the Fourth Industrial Revolution and emerge as leaders in their fields.

As we move forward, it’s clear that the combination of technological innovation and an entrepreneurial spirit will be the driving force behind industry transformation. What are your thoughts on fostering an entrepreneurial mindset within your organization? Share your experiences and join the conversation below! ⬇️

The Fourth Industrial Revolution, or Industry 4.0, is transforming the manufacturing landscape. It presents exciting opportunities for growth and innovation, but the road to successful adoption can be bumpy. This blog post dives into how fostering a growth mindset can empower manufacturing organizations to overcome these hurdles and unlock the full potential of Industry 4.0.

Understanding the Roadblocks: Industry 4.0 Adoption Challenges

Many manufacturing organizations face significant barriers when embracing Industry 4.0. Here are some common roadblocks:

The Power of Growth Mindset: Unlocking Industry 4.0 Potential

A growth mindset is the belief that your abilities and skills can be developed through continuous learning and effort. By cultivating this mindset across the organization, manufacturing companies can overcome these challenges and unlock the potential of Industry 4.0. Here's how:

Actionable Strategies for Building a Growth Mindset

Here are some concrete steps manufacturing organizations can take to cultivate a growth mindset:

Breaking Down Silos and Embracing the Future

By fostering a growth mindset, manufacturing organizations can break down internal silos, empower teams, and fully embrace the transformative potential of Industry 4.0. Here's what this looks like:

Ready to Lead the Manufacturing Revolution?

With a growth mindset, your manufacturing organization can become an industry leader in the era of Industry 4.0. By overcoming these challenges and adopting the strategies outlined above, you can unlock new levels of efficiency, innovation, and ultimately, success.

Join the Conversation!

We'd love to hear your thoughts! Share your experiences and insights on how your manufacturing organization has overcome Industry 4.0 barriers with a growth mindset. Let's learn from each other in the comments below!

Imagine a factory floor abuzz with cutting-edge automation, yet crippled by outdated mindsets. This is the reality for many manufacturers struggling with digital transformation.

Digital transformation is crucial for staying competitive in today's fast-paced market, but many manufacturers remain stuck in the Industrial Age. Let's explore four mindsets that are holding back successful digital transformation in manufacturing and discuss how to overcome them.

In the world of manufacturing, digital transformation is no longer a luxury—it's a necessity. However, many manufacturers are still clinging to outdated mindsets that prevent them from fully embracing modern technology. This article will delve into four common mindsets that hinder successful digital transformation in manufacturing and offer practical solutions to overcome these barriers. By breaking free from these limiting beliefs, manufacturers can unlock new levels of efficiency, productivity, and competitiveness.

One of the most pervasive mindsets in manufacturing is the idea that if something isn't broken, there's no need to fix it. This attitude can be particularly damaging in a rapidly evolving digital landscape.

Relying on outdated software and systems might seem cost-effective, but it can lead to inefficiencies and security vulnerabilities. For instance, an old manufacturing execution system (MES) might not integrate well with new technologies, making it difficult to adapt to changing customer demands.

Consider a manufacturer that continues to use decades-old software for production management. This software may be reliable but lacks the flexibility to incorporate new features or improvements. As a result, the company struggles to meet customer expectations, leading to lost business opportunities.

To break free from this mindset, manufacturers need to recognize the long-term benefits of modernizing their systems. Regularly evaluating and updating technology can improve efficiency, reduce costs, and enhance security.

Many manufacturers hesitate to invest in digital transformation due to the perceived high costs. However, this mindset overlooks the long-term financial benefits of modernization.

While the initial investment in new technology can be significant, the cost of inaction is often higher. Outdated systems can lead to production delays, increased downtime, and higher maintenance costs, all of which negatively impact the bottom line.

A company might hesitate to invest in an Industrial Internet of Things (IIoT) solution due to upfront costs. However, without this investment, they continue to experience frequent machine breakdowns and production delays, leading to lost revenue and customer dissatisfaction.

Investing in digital transformation can lead to significant cost savings and increased productivity in the long run. By automating processes and leveraging data analytics, manufacturers can optimize operations, reduce waste, and improve decision-making.

Another common barrier to digital transformation is the belief that the necessary expertise is lacking within the organization.

Rather than viewing this as an insurmountable obstacle, manufacturers should embrace collaboration. Partnering with IT professionals, consultants, and technology vendors can bridge the knowledge gap and ensure successful implementation.

A factory might lack the in-house skills to implement a new cloud-based MES system. By partnering with a consulting firm, the factory can successfully deploy the system and receive ongoing support, ensuring a smooth transition and continuous improvement.

In addition to external collaboration, investing in employee training and development is crucial. Providing employees with the skills and knowledge they need to work with new technologies can foster a culture of continuous improvement and innovation.

Change can be daunting, especially in a manufacturing environment where stability and predictability are valued. However, resistance to change can hinder progress and competitiveness.

Manufacturers need to foster a culture that embraces change and continuous improvement. This involves regularly evaluating processes, seeking feedback from employees, and being open to new ideas and technologies.

A manufacturing plant might resist implementing a new automation system due to fears of disruption. However, by involving employees in the planning and implementation process and providing adequate training, the transition can be smooth and beneficial for everyone.

Effective change management strategies can help minimize disruption. Clear communication, employee involvement, and phased implementation can ease the transition and ensure that changes are well-received and integrated smoothly.

Overcoming these limiting mindsets requires a shift in perspective. Manufacturers need to view digital transformation not as a disruptive force but as an opportunity for growth and improvement.

Taking a proactive approach to digital transformation can lead to numerous benefits, including increased efficiency, reduced costs, and enhanced competitiveness. By staying ahead of technological trends, manufacturers can position themselves for long-term success.

Developing a clear roadmap for digital transformation can help manufacturers navigate the journey. This involves setting clear goals, identifying key technologies, and establishing a timeline for implementation.

To thrive in today's competitive landscape, manufacturers must break free from the mindsets that hinder digital transformation.

Leadership plays a crucial role in driving digital transformation. Leaders need to champion change, allocate resources, and create a vision that inspires and motivates employees.

Encouraging a culture of innovation can help manufacturers stay ahead of the curve. This involves rewarding creativity, fostering collaboration, and being open to new ideas and approaches.

Strong leadership is essential for successful digital transformation. Leaders need to communicate the vision, allocate resources, and drive change throughout the organization.

Leaders should clearly articulate the vision for digital transformation and ensure that it aligns with the overall business strategy. This vision should be communicated to all employees to ensure buy-in and support.

Digital transformation requires investment in technology, training, and support. Leaders need to allocate the necessary resources to ensure that the transformation is successful.

Technology is a key enabler of digital transformation. Manufacturers need to leverage the latest technologies to stay competitive and drive growth.

Data analytics can provide valuable insights into operations, helping manufacturers optimize processes, reduce waste, and improve decision-making. By harnessing the power of data, manufacturers can gain a competitive edge.

Automation and robotics can significantly improve efficiency and productivity. By automating repetitive tasks, manufacturers can free up employees to focus on higher-value activities.

Continuous improvement is essential for staying competitive in today's fast-paced market. Manufacturers need to regularly evaluate and improve their processes to stay ahead.

Investing in employee training is crucial for continuous improvement. Providing employees with the skills and knowledge they need to work with new technologies can drive innovation and improvement.

Regularly seeking feedback from employees can help manufacturers identify areas for improvement and make necessary changes. This feedback loop is essential for continuous improvement and innovation.

Collaboration is key to successful digital transformation. Manufacturers need to create a culture that encourages collaboration and teamwork.

Creating cross-functional teams can help break down silos and encourage collaboration. These teams can bring together different perspectives and expertise, driving innovation and improvement.

Partnering with external experts can provide valuable insights and expertise. Manufacturers can leverage the knowledge of consultants, technology vendors, and other partners to drive digital transformation.

Investing in employee training is essential for successful digital transformation. By providing employees with the skills and knowledge they need to work with new technologies, manufacturers can drive innovation and improvement

Designed by W3Squad