Digitalization has been causing tectonic shifts in industry after industry even before the pandemic hit us. Artificial intelligence, big data analytics, cloud, the Internet of Things and other digital technologies are decimating the old ways of running businesses and creating new business models and revenue streams.

So, what will happen in the post-pandemic world? Most certainly, we feel, that these shifts will accelerate and those who invest early in digital transformation will thrive. Others may not survive at all.

Companies may need to urgently recalibrate their vision, mission and strategies to remain relevant. Some obvious effects will be:

One way to think about the future of our business is to imagine how we can Amazon-ise (or Google-ise/Uber-ise/Tesla-ise/Airbnb-ise) it - and even take it beyond that!! There is, however, no escape from making the leap towards digital transformation.

We, at Digi2O, have created intelligent digital systems that support informed and accelerated decision making, which improve the efficient use of capital and boost the ROCE / ROI for businesses.

We will be happy to share with you our capabilities over an interactive video session and understand how we can empower your business and improve its capability to survive such shocks in the future.

Please feel free to write back to me or request for a call back for a video session.

We pray for your good health and future and look forward to speak to you soon.

I have been in conversation with a large manufacturing company who need support for an assembly line test equipment and data analytics. (This is an interesting story by itself and I shall talk about it in a later article.)

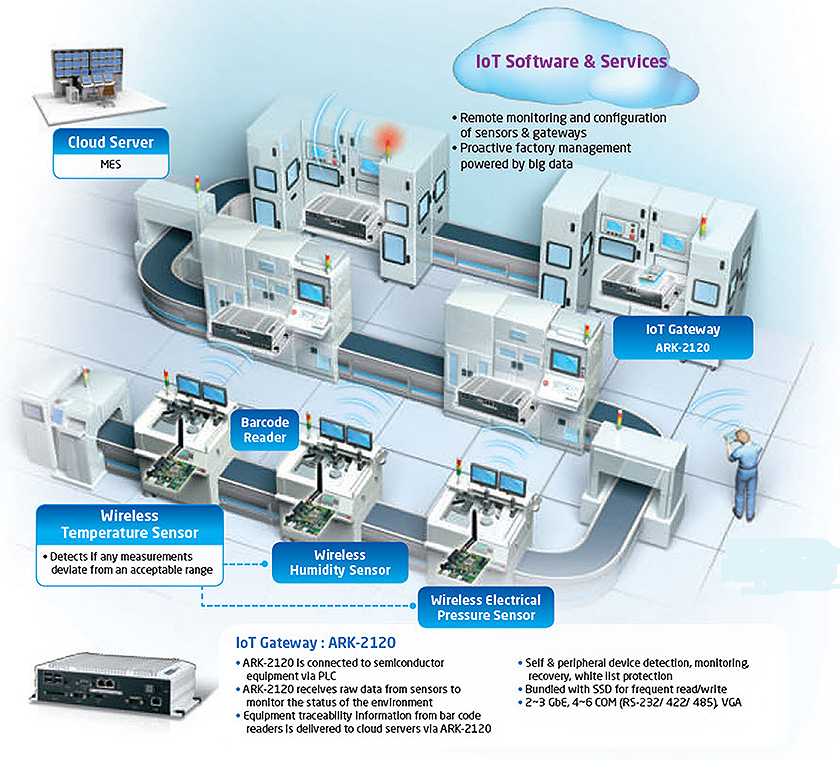

I came to know recently from them that a team there is also looking to retrofit solutions to their production machines on the shop floor to collect real-time data.

There is a need of retrofitting IoT solutions to their existing machines since the equipment OEMs may not have necessarily designed their machines with these solutions. Note that only very lately the equipment manufacturers are putting strategies in place to build ‘connected’ machines.

There is a strong case for equipment owners to gather intelligence from their ‘connected’ machines and ‘listen’ to what these machines are ‘saying’. This helps you to truncate costs in many ways. You can prevent breakdowns and increase up time. You can ensure optimal inventory and usage of spares. You can plan and schedule your equipment usage better. You can run an effective maintenance department with better planning of maintenance personnel. Better life of your machines is likely to reduce your future capital expenses. The connected intelligence of interconnected machines can even fully automate your shop floor. The world is inexorably moving in this direction.

Per a recent survey in the US, nearly 90% of the manufacturers are using or exploring the use of IoT technology to enhance operations.

There is a happy spin-off of investing in retrofitting IoT solutions to your machines. The data that you gather over a period is a goldmine for the OEMs who have built those machines. The analytics from this data can help the OEMs design and build machines that are of improved quality, usability, reliability and safety.

Such information from the field can throw light on usage duration, user behavior, user preferences, usage environment, failure modes, mean time between and to failure, mean time to repair, efficiency of the system and the sub-systems and a host of other parameters that can provide significant inputs for design and product quality improvements and eventually customer delight for the OEMs.

So, there is a very strong case for equipment owners to collaborate with their equipment suppliers and share with them the intelligence gathered over time. The OEMs will be happy to pay for such a service. Such a symbiotic arrangement is a win-win for both parties.

The survey quoted earlier also mentions that 86% of the product manufacturers in the US who were surveyed have either built or started building IoT solutions within their products precisely for the reasons quoted above. Now, how good it would be for the equipment owners to feed this ready information back to them?

To produce the intelligence from the data the equipment owners do not need to invest in a department full of data scientists! Such services are available on demand and they can utilize them on a case to case basis. Perhaps the company they engage to retrofit the IoT solutions can help on this. (This is assuming that the retrofitting is not being done in-house.)

iPhone X is out. The most hyped feature on this mean machine is its 3-D facial recognition feature which authenticates the user before the phone can be opened and used. In other words, you can now say good bye to fingerprint, PIN or password based authentication.

Apparently, the feature is pretty accurate and it cannot be fooled by disguises or using masks. It captures some 30,000 points of your face and creates a 3 D map and stores it in a chip within the device in encrypted form for security.

Facial recognition technology is getting better and better, though there are potentially huge security and privacy issues involved (and which we shall discuss in a later article). But for now, let’s do some blue sky thinking on at least one beneficial way facial recognition can be used in tandem with other technologies and artificial intelligence.

Well I do not really mean to be so dramatic, but can we ignore the realities that we see around us today?

I had an uncle who was retired and rich and would spend a good amount of time sitting in the balcony reading newspapers and magazines. But any suspicious goings on in the street below would not escape his eye. His vigilance stood him and the neighbourhood in good stead.

But such human dependent vigilance can be flawed and is likely to miss important events once in a while. Enter the heroes of the new era - CCTV camera and Aadhar – the last being considered more a villain than a hero nowadays.

Imagine that someone is recceing my house with the intention of theft or perhaps murder. (No harm in imagining things!!) The person comes on his bike and runs down the road glancing at my property, turns around and goes back, glancing again all the way. He does this a few times over the day or over a few days.

There are several CCTV cameras on the road and outside my house as well. All of these are connected to a data centre where an AI algorithm runs on the videos being fed to it in real time. The AI algorithm has ‘learnt’ over the past several months or years to know that this person’s frequent movement in front of my house could be a ‘suspicious’ event. Very much like what my uncle would have surmised.

Now, that is what AI is meant for. It is supposed to learn by experience what we as human beings have learnt by experience and come to same or similar conclusions on its own and even faster than what we can do.

The system then raises an alarm since it has detected an anomaly – in this case the alarm can come to me, my neighbors and even the police - via phone call or SMS or a buzzer or whatever.

Now imagine that the police have access to the data center server where the video gets streamed and have this integrated with the Aadhar database. Now, Mr. Thief, if he has to live in this country, must definitely have his Aadhar stored there – right? In all likelihood, if the CCTV footage is reasonably good, another piece of AI algorithm will be able to find in minutes, if not seconds, the right match between the face on the CCTV footage and the Aadhar photograph.

I leave the rest of this whodunit to be completed by you, dear reader.

Can the technology go wrong? Of course, it can. Perhaps the chap was actually innocent. But then my uncle’s hunches could be wrong as well. But that does not mean that uncle would not at least get up and verify and assure himself that all was OK. Same is with the AI system.

Well, all of this is now in the realm of possibility though not used in the fashion as described in this story. Such intelligent technologies can ensure better safety and security to citizens at a cost/effectiveness ratio that is much lower than current methods. But there could be privacy and legal issues to be grappled with to make this happen.

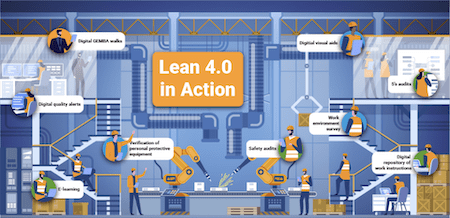

Over the years ‘Lean’ has become one of the most practiced methodologies for manufacturing industries to become more profitable. Lean principles are quite generic and are now used by the services industry also.

At the core of the Lean is the philosophy of generating more value for your customer by reducing waste. As manufacturing embraces Industry 4.0 the question is if this is a new trend that will replace Lean on the shop floor.

Actually, before any such thing happens to the detriment of the progress made over the years with Lean, it must be understood that the question is wrong. These are two different things. But at the same time Industry 4.0 can be a potent tool to support Lean.

While Lean relies on practices and methods to reduce waste, increase value and become more effective and efficient, Industry 4.0 is all about creating an ecosystem of connected machines and processes that provides the necessary intelligence in a timely manner for taking the right action.

We examine below a few of the Lean concepts and practices that can be augmented by the automated information and intelligence system derived from Industry 4.0. (In some cases, we shall use the Japanese terms that are used in the context of Lean, since Lean is actually a synonym for TPS or Toyota Production System which originated in Toyota in Japan.)

Muda is the waste of non-value add activities. The most famous sub-categories of this waste category are the wastes of Transport, Inventory, Motion, Waiting, Overproduction, Over-processing and Defects. With an Industry 4.0 backbone, information from material, products, material handling equipment, transportation vehicles, machines, testing equipment and even humans who handle the processes can travel and be analysed very quickly to minimize waste from all of these sources. Read about an example here on how IBM has created a visual inspection method using an IoT solution that reduces inspection time and supports reduction of defects.

Mura is the waste of inconsistency. Practitioners of statistical process control (SPC) and Six Sigma understand the value of a consistent process. Inconsistent or ‘out-of-control’ processes produce waste by increasing defects, raising inventory and waiting time and doing overproduction. When processes generate real-time data, it is possible to detect inconsistency rapidly and even self-regulate to remove the inconsistency as rapidly.

Additionally, Mura indicates the waste that happens due to irregularities caused by imbalance of demand and capacity that impact resource and operator availability and utilization. Lean techniques for leveling load such as heijunka and Kanban can be augmented by the real-time information and data analytics that are generated using the information backbone provided by the connected assets.

Muri is the waste of excessive stresses and strain that is inflicted upon both humans and machines. The just-in-time production processes aided by information and analytics can considerably reduce the undue stresses and strains on assets and even enhance productive life.

No problem can be solved effectively and from the root without these – so says the Toyota Production System. Gemba means the real place. In other words, you have to be at the real place of the problem to understand it properly. Similarly, Gembutsu refers to the real thing. You cannot solve a problem without seeing or touching the real thing. Genjitsu refers to real data. Lean is data driven and without real data a problem cannot be solved permanently.

Whilst, the information highway created by Industry 4.0 can ensure Genjitsu or Real Data, very soon we may see immersive technologies such as augmented reality (AR) help in Gemba and Gembutsu (real place, real thing, almost!) so that technicians can study and troubleshoot remotely.

At the heart of Industry 4.0 (some may prefer to call it the edge) are the sensors that can be attached to machines and devices. Such sensors can play a major part in mistake proofing processes so that faults, failures and defects are prevented. Data from sensors attached to jigs and fixtures, dies and tools can raise alarms or stop processes when anomalies are detected.

We talk about autonomous cars these days. The word autonomation came directly from the terminology used in the TPS, translated from the word jidoka in Japanese. This means providing hi-tech sensing equipment in machines that will prevent the machines from producing defects. The connection of Jidoka with Industry 4.0 is obvious.

As is evident from the above we can expect Lean Manufacturing and Management to be more successful with the support of Industry 4.0, which is expected to play a supplementary role to Lean by providing real data, at real time with actionable intelligence. Conversely, Lean can drive implementation of Industry 4.0 by drawing up goals, objectives and plans that provide inputs for the Industry 4.0 implementation plan.

In a recent visit to a customer’s plant we were provided with a thought-provoking use case. The plant produces automobile sheet metal parts. The customer asked if we could in some way help them track the part produced beyond its assembly at the automobile manufacturer’s factory and into the lifetime of the vehicle while it is being used by the vehicle owner.

The request, by itself, is not unusual since there has been a requirement of ‘traceability’ in the automotive and other engineering industries. Traceability allows product manufacturers to trace back from the product and answer questions such as who produced it, when it was produced, when was it tested, who tested it, what were the test results and so on. This information becomes vital for doing root cause analysis when there is product failure in the field and reduce warranty costs.

Currently, manufacturers do use manual and some automated or semi-automated methods to comply with traceability requirements.

However, the customer’s question triggered a train of thought based on what we already know about the immense possibilities of products and processes all tied together through common information in the new connected world.

There is still some distance to travel in this direction. Physical flow of material and the information flow with regard to the material are still mostly separated and they need to be coordinated and synchronized to make meaning. This results in errors and delays.

In contrast, with IoT technologies, it will be possible to ingrain the information into the product itself, thus making it possible for the product information to travel along with the product. This has far more profound consequences than just the goal of fully automated traceability.

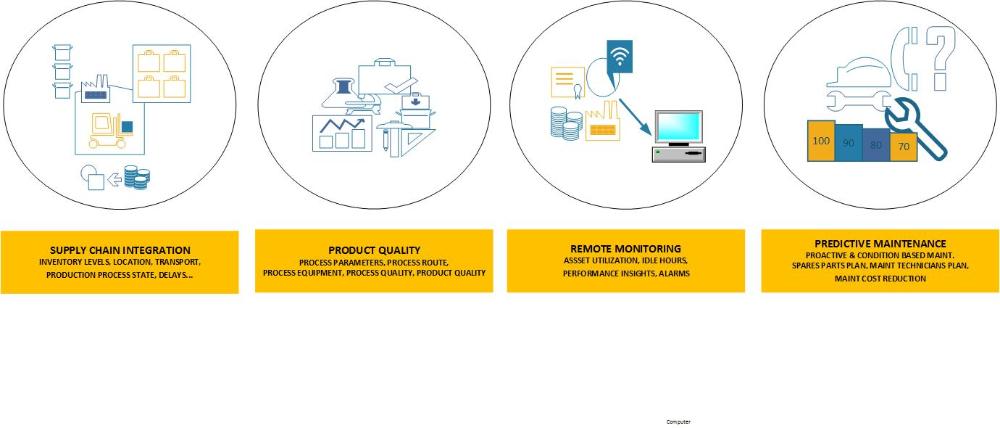

Below are four areas where such an ‘information-in-product’ solution can have far reaching benefits.

Imagine that a piece of raw material in form of a hot rolled steel coil produced by the supplier contains within it the information about its specs, the customer for which it is intended, its transport information and its geographical location as it travels from the supplier to your plant. Your supply chain managers are made aware of this information real time which helps them make decisions about inventory levels, further orders, storage locations where it needs to be stored and so on. Once it arrives it automatically updates the incoming material warehouse that it has arrived thus updating the local inventory level. As the coil is moved through the plant floor from the stores you are aware where it is lying at every stage.

Since it is a coil it is cut into pieces. Each piece now can carry its own information but at the same time be tagged with the mother coil’s information. Each piece can now be tracked as it moves from process to process until it is packed and dispatched. As it now moves to your customer’s plant it can be tracked and also tagged with the final product (such as a vehicle) in which it is assembled. As the final product is moved to the dealer’s / retailer’s warehouse and from there to the end customer you know the location of the part, the end product to which it is fitted and also perhaps who the end customer is!

Now, going back to the coil when it was received by you in your stores. Your planning managers can embed information such as work order number, the machines/lines to which it will be fed, the tools and dies that will be used, the packaging material that will be needed and so on, as it moves from one operation to another. Thus, if, in error, it is moved to a machine which is not in its route as planned it can generate alarms.

The part produced from the coil will have similar information and more. It will have the process information of the machines, tools/dies, inspection instruments, operators, inspectors/testers and perhaps even the test results/certificates related to the part.

Coupled with the data from the process through which the product passes, this complete information can be very potent. For instance, if in a spot welding process there was an instantaneous power surge which could have likely weakened the weld, this information could be used to identify exactly which piece would have been defective and it then taken off the production line.

When the product is out in the field you can monitor the number of hours it had run, number of hours it had remained idle, whether it was repaired or maintained or whether it was replaced and discarded.

Alerts based on system thresholds or specific event related alerts can be set based on which the owner/user of the product, the service technician and the manufacturers – both the OEM and the part supplier - can be alerted for any pre-emptive actions. This can lead to better safety, comfort of use and longer life of the product.

More importantly, the real-time data emanating from the product as it is used in real life can add valuable insights in terms of future product quality and reliability improvements through design and process advancements.

Finally, the embedded information in the product can support proactive and condition based maintenance of the product by generating performance data on a real-time basis and make you aware of its current health condition. You may therefore plan for spares at the right time, plan for your maintenance resources accordingly and more importantly prevent a breakdown from happening. You also can ensure that you maintain it only when it is required to be maintained based on its real-time condition and thus avoid costly maintenance activity that may include premature replacement of the part.

Embedding life stories into your products from cradle to grave is fast becoming a reality. This has major ramifications that has potential to impact your supply chain effectiveness, product quality and after sales service. Indeed, we can expect the service aspect to become more dominant in terms of revenues with ‘as-a-service’ based revenue models underpinned by data collected and analyzed from products, processes and supply chains.

Designed by W3Squad