Introduction :

As we embrace the digital age, the concept of Industry 4.0 has emerged as a transformative force, revolutionizing the way industries operate. Industry 4.0, characterized by the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence, big data, and automation, promises increased efficiency, productivity, and competitiveness. However, to harness the true potential of Industry 4.0, a robust and well-structured information architecture is essential. In this blog, we will explore how a structured information architecture forms the backbone of a successful Industry 4.0 implementation and how it unifies and augments existing IT infrastructure to create a resilient ecosystem that maximizes the benefits of the program.

1. Understanding the Foundations of a Structured Information Architecture

A structured information architecture is a strategic framework that ensures data flows seamlessly across an organization's IT systems, processes, and decision-making procedures. It comprises three foundational pillars that act as the cornerstone of a successful Industry 4.0 implementation: Information Governance, Integration of diverse IT systems, and Processing of captured information.

1.1 Information Governance

Information Governance is the process of managing, protecting, and leveraging an organization's data assets. In the context of Industry 4.0, data becomes a critical resource driving innovation, optimization, and efficiency. Proper Information Governance establishes guidelines for data ownership, data quality, security, and compliance, ensuring that data is reliable and trustworthy. By implementing robust Information Governance practices, organizations can make better decisions based on accurate and timely information.

1.2 Integration of Diverse IT Systems

In most industries, IT landscapes have evolved over time, resulting in a patchwork of disparate systems and applications. These systems may not communicate effectively with each other, leading to data silos and inefficiencies. To create a resilient Industry 4.0 ecosystem, unifying these diverse IT systems is crucial. Integration enables data to flow seamlessly between different departments, processes, and devices, facilitating a holistic view of operations. This integration not only improves collaboration but also paves the way for more informed decision-making.

1.3 Processing of Captured Information

The data generated by Industry 4.0 technologies can be vast and complex. Effectively processing this data is essential to derive valuable insights. Advanced analytics, machine learning, and artificial intelligence are instrumental in transforming raw data into actionable intelligence. By extracting meaningful patterns and trends from the captured information, organizations can make data-driven decisions, optimize processes, and identify new opportunities for innovation.

2. The Role of Resilient IT Ecosystem in Industry 4.0

A resilient IT ecosystem is a result of the unification and augmentation of existing IT infrastructure. It is designed to withstand disruptions, scale with business needs, and adapt to rapidly changing technologies. Such an ecosystem is fundamental to the success of Industry 4.0 as it enables organizations to leverage the full potential of digital transformation.

2.1 Unification of IT Infrastructure

The first step in creating a resilient IT ecosystem is breaking down data silos and establishing seamless integration between disparate systems. Cloud computing plays a pivotal role here, providing a centralized platform for data storage, processing, and accessibility. Cloud-based solutions allow real-time collaboration and enhance data mobility, which are essential in an Industry 4.0 context where data-driven decisions often need to be made in real-time.

2.2 Augmentation of IT Infrastructure

Augmentation of IT infrastructure involves the deployment of cutting-edge technologies that complement existing systems. This could include IoT devices, sensors, and smart machinery that generate valuable real-time data. By incorporating these technologies into the ecosystem, organizations can capture more comprehensive data sets and enable a deeper understanding of their operations. Additionally, deploying AI and machine learning algorithms empowers the system to learn from data patterns and continuously improve processes.

3. Empowering Employees through Data-Driven Decision Making

In Industry 4.0, data is the backbone of decision-making. A structured information architecture empowers employees at all levels to make data-driven decisions, fostering a culture of continuous improvement and innovation.

3.1 Accessibility and Visualization of Data

By unifying and integrating IT systems, relevant data becomes readily accessible to employees across the organization. Modern data visualization tools provide intuitive interfaces for data analysis, making it easier for employees to interpret complex data sets. Visualization simplifies the decision-making process, enabling employees to identify patterns and trends quickly.

3.2 Real-Time Decision Support

The integration of Industry 4.0 technologies allows for real-time data capture and processing. As a result, employees can receive instant alerts and notifications, enabling them to respond promptly to critical situations. Real-time decision support enhances operational efficiency, minimizes downtime, and optimizes resource utilization.

3.3 Predictive and Prescriptive Analytics

One of the most significant advantages of Industry 4.0 is the ability to leverage predictive and prescriptive analytics. Predictive analytics uses historical data and machine learning algorithms to forecast future events, while prescriptive analytics suggests optimal actions to achieve desired outcomes. By incorporating these analytics capabilities into the decision-making process, organizations can anticipate challenges, mitigate risks, and identify growth opportunities proactively.

Conclusion

In conclusion, a structured information architecture is the backbone of a successful Industry 4.0 implementation. It unifies and augments existing IT infrastructure, creating a resilient ecosystem that maximizes the benefits of digital transformation. The three foundational pillars of Information Governance, Integration of diverse IT systems, and Processing of captured information play a crucial role in shaping the information architecture. Moreover, a well-designed IT ecosystem empowers employees with data-driven decision-making capabilities, driving efficiency, innovation, and competitive advantage in the Industry 4.0 landscape.

Embracing a structured information architecture is not a one-time endeavor but an ongoing journey of adaptation and optimization. As technology continues to evolve, organizations must remain agile and responsive, continuously seeking new ways to harness the power of data and technologies to thrive in the dynamic world of Industry 4.0.

In the fast-paced world of technology, IoT (Internet of Things) projects have become a driving force behind innovation and efficiency. Organizations across industries are embracing the potential of IoT to enhance operations, improve customer experiences, and drive revenue growth. However, building a robust business case for IoT projects is no small feat. In fact, it is a major task in itself, presenting a myriad of challenges that demand careful consideration and strategic planning.

Challenges in Creating a Business Case for IoT Projects

1. Defining Clear Objectives :

One of the primary challenges in building an IoT business case is defining clear and measurable objectives. Without a well-defined purpose, it becomes challenging to assess the potential benefits and outcomes of the project. An unclear vision may lead to misguided decisions and investments, ultimately impacting the project's success.

2. Data Privacy and Security Concerns :

IoT projects involve the collection, transmission, and analysis of vast amounts of data from connected devices. Ensuring the security and privacy of this data is paramount. Organizations need to address potential vulnerabilities, implement robust encryption mechanisms, and comply with data protection regulations to gain stakeholders' trust.

3. Cost and Resource Allocation :

Implementing IoT projects requires significant financial investments and allocation of resources. Convincing stakeholders to allocate budgets and prioritize IoT initiatives amidst competing projects can be an uphill battle. Demonstrating a clear return on investment (ROI) is essential in securing necessary resources.

4. Integration with Existing Infrastructure :

Most organizations already have established systems and processes in place. Integrating IoT solutions with existing infrastructure can be complex, as it involves seamless connectivity, data synchronization, and interoperability. Failure to address integration challenges may lead to inefficiencies and disruptions in operations.

5. Risk Mitigation Strategies :

IoT projects introduce new risks, such as technical malfunctions, data breaches, and compatibility issues. Developing comprehensive risk mitigation strategies and contingency plans is crucial to minimize potential setbacks and ensure project success.

6. Cultural and Organizational Change :

Embracing IoT often requires a cultural shift within an organization. Employees may need to adapt to new technologies, processes, and ways of working. Effective change management practices are necessary to overcome resistance and foster a supportive environment for IoT implementation.

7. Predicting Long-Term Benefits :

While the benefits of IoT projects are promising, accurately predicting the long-term impact can be challenging. Factors like market dynamics, technological advancements, and changing customer demands can influence the project's long-term success.

8. Stakeholder Alignment :

IoT projects involve multiple stakeholders, each with their own set of expectations and priorities. Achieving alignment among stakeholders, including executives, IT teams, and end-users, is crucial for smooth project execution and achieving desired outcomes.

Overcoming the Challenges: Building a Compelling IoT Business Case

To overcome the challenges and build a compelling IoT business case, organizations need to adopt a systematic and strategic approach. Here are some key steps:

1.Comprehensive Market Research

Thorough market research is fundamental in understanding the industry landscape, identifying competitors, and spotting opportunities for IoT implementation. Gather insights on market trends, customer demands, and potential areas for improvement through IoT integration.

2. Clear Objectives and Goals

Define clear and well-defined objectives for the IoT project. Align these objectives with the organization's overall strategy and identify the specific metrics that will measure success. Ensure that each goal is realistic and achievable within the project timeline.

3. Risk Assessment and Mitigation

Conduct a comprehensive risk assessment to identify potential challenges and vulnerabilities. Develop robust risk mitigation strategies and outline contingency plans to address unexpected issues.

4. Demonstrate ROI

Quantify the potential return on investment (ROI) of the IoT project. Calculate both tangible benefits, such as cost savings and revenue growth, and intangible benefits, such as improved customer satisfaction and enhanced brand reputation.

5. Data Security and Privacy Measures

Address data security and privacy concerns proactively. Implement industry-leading security protocols, encryption methods, and compliance measures to safeguard sensitive information.

6. Collaborative Stakeholder Engagement

Involve stakeholders from various departments in the decision-making process. Collaborative engagement fosters buy-in, ensures all perspectives are considered, and paves the way for a smoother implementation.

7.Pilot Projects and Proof of Concept

Before full-scale implementation, conduct pilot projects and proof of concept initiatives. These smaller-scale trials allow for testing and refinement, providing valuable insights before investing significant resources.

8. Scalability and Flexibility

Ensure that the IoT solution is scalable and adaptable to future needs. Future-proofing the project enables seamless expansion and integration with emerging technologies.

9. Employee Training and Support

Invest in comprehensive employee training to equip the workforce with the necessary skills to embrace IoT technologies effectively. Offer ongoing support and assistance during the transition period.

10. Continuous Monitoring and Optimization

IoT projects are dynamic and ever-evolving. Implement continuous monitoring and optimization processes to track performance, identify areas for improvement, and stay ahead of the curve.

Conclusion

Building a robust business case for IoT projects is a critical step towards harnessing the potential of this transformative technology. By addressing challenges head-on and following a strategic approach, organizations can create a compelling case that garners support and paves the way for successful implementation.

Remember, the success of an IoT project relies not only on the quality of the technology but also on the thoroughness and persuasiveness of the business case. By carefully considering the challenges, conducting in-depth research, and outlining a well-structured plan, your organization can lead the way in leveraging IoT to drive innovation and growth.

Introduction

In the world of manufacturing and service industries, ensuring high-quality products and services is paramount to achieving customer satisfaction and maintaining a competitive edge. One of the key factors that contribute to this is process capability, which involves consistently delivering parameters within designed tolerances. To further enhance the monitoring of process capability and prevent defects, we now have the power of the Internet of Things (IoT) at our disposal. In this blog, we will delve into the importance of process capability, the real-time monitoring using IoT devices, and the significant role they play in defect prevention.

What is Process Capability?

Process capability refers to the ability of a process to consistently produce output that meets the desired specifications. In other words, it ensures that the process is stable and capable of delivering results within the defined tolerances. This is a crucial aspect of maintaining high-quality products and services while minimizing waste and meeting customer expectations. By continuously measuring process capability, organizations gain valuable insights into the performance and stability of their processes, allowing them to make data-driven decisions for continuous improvement and defect prevention.

Real-Time Monitoring with IoT Devices

The advent of the Internet of Things (IoT) has revolutionized various industries, and the field of process improvement is no exception. With the help of IoT devices, we can now monitor process capability in real-time, providing an unprecedented level of control and visibility into ongoing operations. These IoT devices are embedded with sensors that capture data on critical process parameters continuously. This data is then transmitted to a central system, where it is analyzed in real-time.

By employing real-time monitoring through IoT devices, organizations can swiftly detect any variations or trends that suggest a shift in the measured parameters. Statistical techniques can be applied to identify potential out-of-control processes. These trends could be indicative of deviations from the desired tolerances, and if left unaddressed, they might lead to defects in the final output.

Process Capability for Defect Prevention

Early detection is key to preventing defects, and real-time monitoring with IoT devices enables precisely that. By identifying trends and variations in measured parameters promptly, organizations can take immediate corrective action. This timely intervention ensures that processes stay within the specified tolerances, reducing the probability of defects occurring.

The ability to monitor process capability in real-time has a direct impact on defect prevention. Detecting and correcting out-of-control processes promptly is the key to preventing defects before they occur. Early intervention ensures that the output consistently meets the specified tolerances, resulting in improved quality and higher customer satisfaction.

When organizations integrate process capability as a fundamental principle of their operations and combine it with automated monitoring using IoT devices, they gain a proactive approach to defect prevention. This not only saves valuable resources that would have otherwise been wasted on producing defective products but also enhances the organization's reputation for consistently delivering high-quality products and services.

Digi2O's Innovative Approach:

Digi2O is committed to employing cutting-edge technologies to ensure the timely correction of out-of-control processes and prevent defects. By harnessing the power of IoT devices for real-time process monitoring, we strengthen our ability to deliver top-quality products and services consistently. This not only benefits our organization but also creates a positive impact on our customers, helping them achieve their goals efficiently and effectively.

Conclusion

In conclusion, process capability is a vital aspect of achieving high-quality products and services while minimizing waste and maintaining customer satisfaction. With the real-time monitoring capabilities provided by IoT devices, organizations can detect out-of-control processes promptly and take corrective action before defects occur. Embracing this innovative approach to defect prevention is a strategic move towards creating a world where excellence is the norm.

As we continue our journey of process improvement and defect prevention, we invite you to stay tuned for more insights into our innovative approach. Like and follow our page to keep up with the latest industry trends and learn how Digi2O is shaping the future of quality and reliability. Together, let's create a world where defects are a thing of the past, and excellence is the standard. ?

Introduction

In the rapidly evolving digital landscape, organizations are continually seeking ways to enhance their capabilities to stay competitive and relevant. The emergence of the Internet of Things (IoT) and Industry 4.0 has revolutionized the business world, offering exciting possibilities for optimizing operations, increasing productivity, and transforming customer experiences. However, one of the principal objectives of IoT/Industry 4.0 goes beyond these benefits—it aims to support organizations in becoming truly agile.

Agility: The Essence of IoT/Industry 4.0

Agility is a defining characteristic of successful organizations in today's dynamic and unpredictable environment. It encompasses the ability of an organization to respond swiftly and effectively to emerging opportunities and challenges. In the context of IoT and Industry 4.0, agility manifests itself through the compression of time between an incident occurring and the organization's capacity to respond appropriately. In simpler terms, it means that organizations can either prevent the incident from happening or minimize the time taken to respond to it.

1. Preventing Incidents: The Power of Proactive Measures

One of the most effective ways IoT and Industry 4.0 support organizational agility is by enabling proactive measures. Connected devices and sensors gather vast amounts of real-time data, providing organizations with invaluable insights into their operations. By analyzing this data, organizations can identify potential risks and vulnerabilities before they escalate into incidents. For instance, predictive maintenance in manufacturing can help detect equipment faults before they cause significant downtime, thus preventing potential losses.

Moreover, IoT-enabled supply chains allow for better tracking and monitoring of goods, reducing the risk of theft, spoilage, or delays. This preventive approach significantly reduces the likelihood of incidents occurring and helps organizations save valuable resources.

2. Rapid Response: Minimizing the Impact of Incidents

Despite the best preventive efforts, incidents may still occur. However, IoT and Industry 4.0 offer valuable tools for minimizing their impact through swift and informed responses. Real-time data streaming from connected devices enables organizations to gain immediate visibility into critical events, empowering them to make well-informed decisions rapidly.

For example, in the case of a cybersecurity breach, IoT devices can detect unusual activities and trigger an immediate response, isolating affected systems and preventing the breach from spreading. In logistics, real-time tracking of shipments allows companies to reroute deliveries promptly in the event of unexpected disruptions, ensuring customer satisfaction and loyalty.

3. Enhancing Decision-making and Adaptability

IoT and Industry 4.0 not only offer real-time data but also facilitate data analytics and artificial intelligence applications. These advanced technologies enable organizations to make data-driven decisions swiftly, enhancing their adaptability to changing circumstances.

For instance, retailers can use IoT data to analyze customer behavior, preferences, and trends. This enables them to optimize their product offerings and marketing strategies in real-time, staying ahead of competitors and meeting customer demands effectively.

4. Seamless Collaboration and Communication

Agility is not solely about individual departments or teams; it requires seamless collaboration and communication across the organization. IoT and Industry 4.0 enable a connected ecosystem where devices, machines, and people can communicate and share information effortlessly.

For instance, in a smart factory, different production stages can communicate with each other, adjusting processes based on real-time data to optimize efficiency. In a smart office environment, employees can collaborate efficiently using connected devices, leading to enhanced productivity and innovation.

5. Agility as a Competitive Advantage

In today's hyper-competitive business landscape, agility can be a differentiating factor that sets organizations apart from their competitors. By leveraging the power of IoT and Industry 4.0, companies can respond to market changes quickly, capitalize on emerging opportunities, and mitigate risks effectively.

Agile organizations are better equipped to navigate uncertainties and disruptions, making them more resilient in the face of challenges. This resilience fosters customer trust and loyalty, leading to long-term success and growth.

Conclusion

In conclusion, the principal objective of IoT and Industry 4.0 is to support organizations in becoming agile. Agility in this context refers to the ability to compress the time between incidents and responses, either through prevention or rapid response. By leveraging IoT technologies, organizations can embrace proactive measures to prevent incidents and minimize their impact through swift and data-driven responses.

The benefits of agility extend beyond risk mitigation; it empowers organizations to capitalize on opportunities, improve decision-making, and foster collaboration across the entire organization. In the digital age, where change is constant and disruptive forces are prevalent, agility becomes a crucial competitive advantage.

As we move further into the era of IoT and Industry 4.0, organizations that embrace and prioritize agility will be at the forefront of innovation, setting new standards for success in an ever-evolving business landscape. The journey towards true organizational agility begins with embracing the transformative potential of IoT and Industry 4.0 technologies.

In a Mckinsey survey of 300 IoT practitioners, 40% identified that discovering and determining use cases and applications as a major capability gap for them. 48% mentioned managing data was another.

Such gaps can, and do, contribute to IoT implementation failures. A study by Cisco found that only 26% of the surveyed companies were successful with their IoT initiatives.

So, do we abandon IoT?

That is not an option.

Consider why: The Mckinsey survey also showed that IoT leaders gained significantly from their IoT projects. Even the IoT laggards claimed reasonable gains.

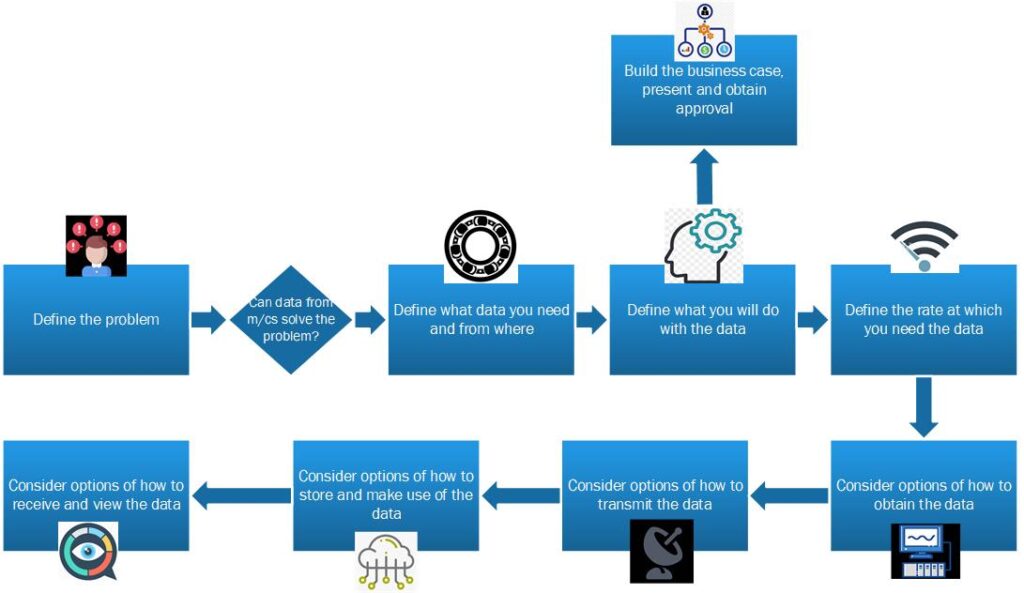

At Digi2O, we believe that the decision making process can be simplified using a basic framework that can ensure a very high probability of success. Suffice is to say that proper strategy and good planning are the keystones of a successful IoT implementation.

IoT projects are essentially data projects. Installing an IoT solution, without giving sufficient thought to why you are collecting the data and what you will do with the data, can be a recipe for disaster.

Below is a view of the framework which we use. It is simple but not simplistic. Zooming into each of the boxes in detail and executing them correctly can help you achieve your IoT objectives with a higher success rate.

I will be happy to speak with you if want to know more about how to go about your IoT project.

Meanwhile, I would like to know about your areas of concern, if any, so that we can serve the community better. Please write back to me in the comments section.

Designed by W3Squad