Introduction

In the ever-evolving world of technology, the demand for faster, more reliable, and seamless connectivity is incessant. The introduction of 5G technology has revolutionized the way we perceive communication and data exchange. In recent years, India has emerged as one of the leading players in the global 5G race, making significant strides to launch and grow this transformative network within its borders. The dawn of the fifth-generation (5G) network has brought with it a revolutionary shift in the landscape of global telecommunications. With its promises of lightning-fast speeds, ultra-low latency, and the ability to connect billions of devices, 5G is set to transform industries and empower societies like never before. India, being one of the world's largest and fastest-growing economies, has embarked on an ambitious journey to embrace this transformative technology.

The Launch of 5G in India

The idea of 5G in India was initially set in motion when the Indian government recognized the potential of this technology to revolutionize various sectors, including healthcare, agriculture, education, and manufacturing. To pave the way for its successful rollout, the government initiated various regulatory and policy reforms to encourage investments and foster innovation in the telecom sector.

Telecom companies in India were eagerly awaiting the 5G spectrum auction, where they would bid for the frequency bands required to offer 5G services. As the auction took place, major players in the Indian telecom industry acquired the necessary spectrum to roll out 5G services in different regions of the country.

Growing 5G Infrastructure

The growth of 5G infrastructure in India has been an exciting journey. Telecom operators, along with equipment manufacturers and vendors, have been working tirelessly to set up the required infrastructure to support 5G networks across the nation. The deployment of small cells, macro cells, and fiber-optic networks has been the backbone of this expansion.

In addition to urban areas, there has been a focus on expanding 5G coverage to rural regions, where a large percentage of India's population resides. This inclusivity is crucial to bridge the digital divide and enable equal access to transformative technologies for all citizens.

The growth of 5G infrastructure also witnessed collaboration between the public and private sectors. The government and telecom companies worked together to establish policies that fostered innovation while addressing security concerns and ensuring compliance with global standards.

As the infrastructure matured, India began witnessing the practical implementation of 5G in various sectors. Some of the key areas where 5G has made a significant impact include:

a. Healthcare: 5G has enhanced telemedicine services, enabling remote consultations, real-time monitoring, and improved connectivity for medical devices. This has been especially beneficial for rural areas with limited access to healthcare facilities.

b. Agriculture: Smart farming solutions powered by 5G have increased agricultural productivity through precision farming, real-time weather data, and IoT-enabled smart devices for efficient resource management.

c. Education: 5G has facilitated remote learning with seamless video conferencing, virtual classrooms, and interactive educational content, making quality education more accessible.

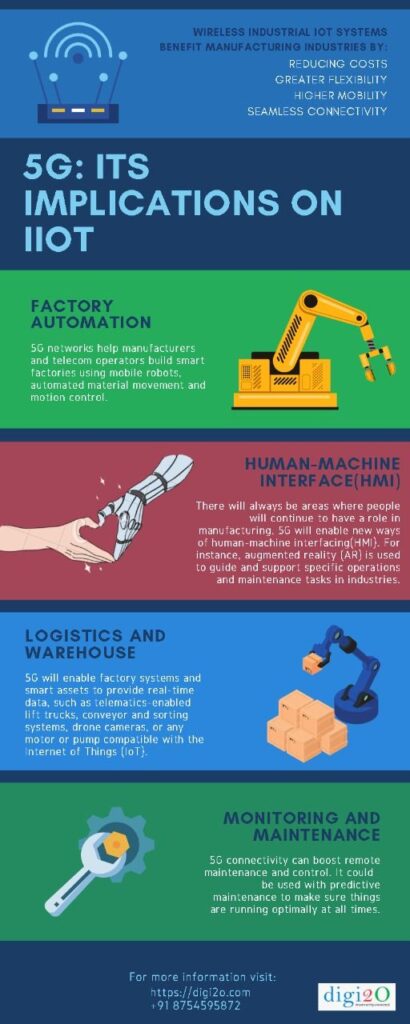

d. Industry and Manufacturing: The implementation of 5G has transformed industries by enabling smart factories with IoT-enabled devices, real-time data analytics, and automation, leading to increased efficiency and reduced operational costs.

e. Smart Cities: 5G forms the foundation of smart city initiatives, facilitating intelligent transportation, smart grids, waste management, and improved public services.

Future Prospects

While the launch and growth of 5G in India have been promising, several challenges remain. Spectrum management, ensuring cybersecurity, and addressing infrastructure gaps in remote areas are some of the hurdles that need to be overcome.

However, India's commitment to the digital future is evident, and as 5G continues to evolve, it is expected to play a pivotal role in India's journey towards becoming a digital powerhouse.

The Genesis of 5G in India

The seeds of 5G were sown in India during the early 2010s when global tech giants started experimenting with the fifth-generation wireless technology. However, it wasn't until 2018 when the Indian government took a proactive stance by forming a high-level committee to study and propose a roadmap for 5G deployment. The committee aimed to create an ecosystem conducive to the successful launch and growth of this cutting-edge technology.

Spectrum Auctions and Regulatory Framework

In 2020, India witnessed its first 5G spectrum auctions. The auctioning of spectrum for the 5G network marked a crucial milestone in India's telecommunications landscape. Telcos competed fiercely to acquire 5G spectrum, showcasing the industry's eagerness to embrace the new era of connectivity. The government also worked on establishing a robust regulatory framework to ensure the efficient and secure deployment of 5G networks across the country.

Collaboration with Tech Giants

To expedite the process of 5G deployment, Indian telecom operators collaborated with international technology companies and equipment manufacturers. These collaborations brought advanced infrastructure, expertise, and investment to the table, propelling India's 5G journey further.

Pilot Projects and Testbeds

Before a widespread commercial launch, numerous pilot projects and testbeds were set up across different cities to evaluate the feasibility and performance of 5G networks. These testbeds provided valuable insights into network efficiency, coverage, and user experience. Various industries, including healthcare, transportation, and education, actively participated in these initiatives, exploring how 5G could revolutionize their respective domains.

Challenges and Opportunities

The path to 5G growth in India wasn't without challenges. The deployment required massive infrastructure investment, considering India's vast and diverse geographical landscape. Addressing concerns related to cybersecurity, data privacy, and health effects of 5G radiation was also paramount. However, with these challenges came tremendous opportunities for the nation's digital transformation.

Benefits of 5G in India

As 5G started gaining momentum, its potential benefits became evident. With faster data speeds and reduced latency, 5G has opened up a world of possibilities for various sectors. Industries like healthcare can now explore telemedicine and remote surgeries, while the education sector can leverage immersive technologies for remote learning. The Internet of Things (IoT) has received a significant boost, enhancing smart city initiatives and industrial automation. Furthermore, 5G has paved the way for enhanced augmented reality (AR) and virtual reality (VR) experiences, transforming entertainment and gaming. The fifth generation of mobile networks, plays a crucial role in enhancing and benefiting In Industry 4.0 it heavily relies on IoT devices to collect data and communicate with each other. 5G's massive machine-type communication (mMTC) capability allows a large number of IoT devices to connect simultaneously, supporting the deployment of a vast array of sensors and devices in smart factories.

Current State of 5G in India

As of 2023 , India has successfully launched 5G services in several major cities. While the network's coverage is still expanding, its initial impact has been promising. Telecom operators continue to invest in infrastructure and technology upgrades, with a focus on enhancing network capacity and reliability. Furthermore, advancements in the development of indigenous 5G technologies have been encouraging, showcasing India's potential to become a global leader in 5G innovation.

Conclusion

The journey of 5G in India reflects the nation's determination to embrace technological advancements and its commitment to providing its citizens with a world-class digital experience. The launch and growth of 5G networks in India have opened up new possibilities for industries, transformed the way we interact with technology, and propelled the nation towards a more connected and digitized future. As India continues to make strides in this realm, one thing is clear – 5G is here to stay, and it holds the key to unlocking a brighter, more innovative tomorrow for India and the world. The launch, growth, and implementation of 5G in India have ushered in a new era of connectivity and possibilities. The transformative potential of this technology across various sectors promises to elevate the lives of millions of people in the country. With a proactive approach from the government, collaboration between stakeholders, and a focus on inclusive deployment, India is poised to leverage 5G to its fullest potential and emerge as a global leader in the digital age. As the world embraces the power of 5G, India stands ready to embark on a journey of innovation, progress, and prosperity.

Introduction

In the realm of manufacturing operations, Industry 4.0 has emerged as a transformative force, reshaping the way industries measure and enhance Overall Equipment Effectiveness (OEE). OEE is a crucial metric that quantifies the efficiency and performance of equipment and processes in manufacturing. By gauging the utilization of machinery, the efficiency of processes, and the quality of output, OEE provides valuable insights into optimizing operations for increased productivity and profitability. In this blog, we will explore how Industry 4.0 is revolutionizing OEE measurement and improvement, leveraging advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), predictive maintenance, adaptive manufacturing, and fostering a culture of continuous improvement.

1. Real-Time Data: Empowering Informed Decision-Making

At the heart of Industry 4.0 lies the Internet of Things (IoT), which enables the collection of real-time data from the manufacturing floor. Gone are the days of relying on manual data collection methods that are often slow and error-prone. With Industry 4.0, manufacturers can now access a constant stream of real-time data, providing a comprehensive view of critical parameters such as machine downtime, production rates, and quality defects. This data-driven approach empowers decision-makers to monitor operations closely and make informed decisions to optimize OEE. The ability to act promptly based on real-time insights allows for swift responses to changing conditions and ensures a significant boost in operational efficiency.

2. Advanced Analytics & AI: Unveiling Hidden Patterns

Industry 4.0 harnesses the power of advanced analytics and AI to unlock meaningful patterns, trends, and correlations within the vast volumes of data generated by IoT devices. These technologies can rapidly process and analyze data, identifying areas for improvement and pinpointing bottlenecks that hinder OEE. By accurately predicting maintenance needs, AI enables manufacturers to take a proactive approach, reducing downtime caused by unexpected equipment failures. This not only optimizes OEE but also minimizes maintenance costs and enhances overall equipment reliability.

3. Predictive Maintenance: Preserving Peak Performance

Predictive maintenance is one of the most impactful applications of Industry 4.0 in manufacturing. By leveraging real-time data and machine learning algorithms, manufacturers can predict when equipment might fail or experience performance degradation. Maintenance teams can then intervene before any breakdown occurs, keeping the machinery in peak condition. This proactive approach not only prevents costly unplanned downtime but also maximizes the lifespan of equipment, further improving OEE metrics.

4. Adaptive Manufacturing: Flexibility for Efficiency

With Industry 4.0, the concept of adaptive manufacturing has taken center stage. This approach empowers machines and processes to dynamically adjust based on changing demands and circumstances. By embracing flexible automation and interconnected systems, manufacturers can significantly optimize OEE. Reduced setup times and improved changeover efficiency contribute to enhanced productivity, as the manufacturing floor quickly adapts to different product requirements. The ability to respond swiftly to customer demands gives manufacturers a competitive edge in the market.

5. Continuous Improvement Culture: Driving OEE Excellence

Industry 4.0 not only provides access to real-time data but also fosters a culture of continuous improvement within manufacturing organizations. By encouraging collaboration and knowledge-sharing among teams, Industry 4.0 enables data-based decision-making at all levels. This data-driven approach empowers individuals to actively contribute to OEE enhancements, making the pursuit of operational excellence a collective effort across the organization. As a result, OEE becomes a central focus, leading to significant improvements in efficiency and overall performance.

Conclusion

The exciting developments in Industry 4.0 have paved the way for a revolution in OEE measurement and improvement. Real-time data, advanced analytics, AI, predictive maintenance, and adaptive manufacturing have collectively transformed how manufacturers optimize their operations. By embracing these technological advancements and fostering a culture of continuous improvement, manufacturers can unlock the full potential of Industry 4.0 to drive operational efficiency, productivity, and competitiveness to new heights. As the journey of Industry 4.0 continues, the possibilities for OEE enhancement remain limitless, promising a brighter and more innovative future for manufacturing industries worldwide.

Introduction

The Industrial Internet of Things (IIoT) has revolutionized the way businesses operate, offering increased efficiency, reduced costs, and enhanced productivity. However, in the pursuit of implementing IIoT solutions, many organizations fall prey to common myths surrounding the importance of creating a robust business case. In this blog, we will debunk three prevalent myths and explore the true value of developing a well-structured business case for IIoT initiatives.

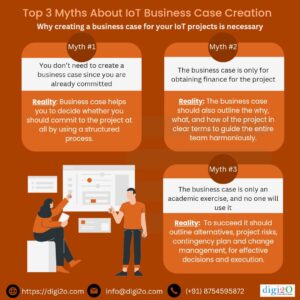

1. Myth: You don't need a business case since you are already committed.

Reality: Commitment is not enough; a business case is vital.

One of the most common misconceptions is that if an organization is already committed to adopting IIoT technology, a business case becomes redundant. While commitment is an essential first step, a comprehensive business case serves as a roadmap, providing clarity on goals, strategies, potential risks, and expected benefits.

A well-documented business case allows stakeholders to align their understanding of the IIoT project's objectives and outcomes. It also aids in identifying potential challenges and mitigating them before they become bottlenecks. Without a business case, businesses may struggle to track progress, evaluate performance, or make informed decisions throughout the project's lifecycle.

A properly developed business case helps in:

a) Setting Clear Objectives: Defining specific, measurable, achievable, relevant, and time-bound (SMART) objectives ensures that everyone involved is on the same page, working towards shared goals.

b) Resource Allocation: It helps allocate resources effectively and justifies the investment of time, money, and human resources into the IIoT project.

c) Risk Mitigation: Identifying potential risks and developing contingency plans strengthens the project's resilience and increases the likelihood of success.

d) Tracking Progress: A well-defined business case facilitates progress tracking and ensures that the project stays on track, delivering the expected benefits.

2. Myth: The business case is only for obtaining finance for the project.

Reality: The business case is much more than a financing tool.

Another common misconception is that the business case solely serves the purpose of securing financial support for the IIoT project. While obtaining funding is undoubtedly a crucial aspect of the business case, it is far from being its only value.

A well-crafted business case acts as a strategic document that aligns the IIoT initiative with the overall organizational objectives. It helps in evaluating the project's viability, considering factors beyond just financial returns, such as competitive advantages, customer satisfaction, and long-term sustainability. Additionally, the business case empowers decision-makers to prioritize projects effectively by comparing potential returns on investment and impact on business goals.

Moreover, the business case also serves as a communication tool, enabling project stakeholders to understand the IIoT project's purpose, benefits, and implementation plan. It fosters collaboration among teams and ensures that everyone is working towards achieving common objectives.

3. Myth: The business case is only an academic exercise and no one will use it.

Reality: The business case is a living document with real-world applications.

Some may view the process of developing a business case as an academic exercise with no practical utility. However, this myth undermines the substantial real-world applications and impact of a well-structured business case.

Throughout the IIoT project's lifecycle, the business case remains a valuable reference document for decision-makers and stakeholders. It helps in maintaining a strategic focus, ensuring that the project aligns with the initial goals and objectives. Moreover, as the project progresses, the business case provides a basis for assessing deviations from the original plan and understanding their implications on the expected outcomes.

Furthermore, the business case serves as a knowledge repository, containing valuable insights and data related to the IIoT project. This information can be utilized for future projects or to improve existing processes, fostering a culture of continuous improvement within the organization.

Conclusion

In conclusion, the business case for IIoT initiatives is far from being a mere formality. It plays a critical role in guiding organizations towards successful implementation and maximizing the benefits of IIoT technologies. Dispelling the myths surrounding the business case highlights its importance as a strategic roadmap, a tool for securing resources, and a living document with real-world applications.

Organizations that invest time and effort in developing a comprehensive business case stand to gain a competitive advantage by harnessing the full potential of IIoT solutions. Remember, a well-structured business case is not just an academic exercise; it is the key to unlocking the true value of IIoT in the industrial landscape.

Introduction:

In today's rapidly evolving business landscape, Industrial Internet of Things (IIoT) initiatives have become a key driver for enhancing operational efficiency, reducing costs, and improving overall business performance. As industries increasingly adopt IIoT solutions, it becomes essential to measure and evaluate the return on investment (ROI) of these projects. Accurate ROI measurement not only justifies the investments made but also helps in optimizing strategies and driving business growth. In this blog, we will explore essential tips to effectively measure the ROI of your IIoT project and unlock its full potential.

1. Set Clear Objectives?:

The foundation of any successful IIoT project lies in defining clear and measurable objectives. Before embarking on an IIoT implementation, businesses must outline their goals, whether it's enhancing operational efficiency, reducing downtime, optimizing resource utilization, or improving product quality. Clear objectives provide a roadmap for the project, making it easier to track progress and assess its impact on the organization.

2. Identify Key Performance Indicators (KPIs)?️:

Aligning the IIoT project with relevant KPIs is essential for effective ROI measurement. These KPIs could vary depending on the specific objectives set for the project. They may include metrics such as increased production output, decreased maintenance costs, enhanced equipment uptime, or improved product quality. By carefully selecting and monitoring these KPIs, businesses can make data-driven decisions and understand the project's overall impact on their operations.

3. Establish Baseline Metrics?:

To measure ROI accurately, it's crucial to establish baseline metrics before implementing the IIoT solution. Baseline metrics represent the performance levels of the processes or systems before the IIoT project's intervention. Comparing these baseline metrics with the data collected after implementation allows businesses to quantify the improvements and validate the success of the project.

4. Leverage Real-time Data Analytics?:

IIoT generates a massive amount of real-time data from connected devices and sensors. This data holds valuable insights into various aspects of the business operations. To make the most of this data, businesses must implement advanced analytics tools that can process and interpret the information effectively. Real-time data analytics enables the identification of trends, detection of anomalies, and proactive decision-making to optimize processes and enhance ROI.

5. Calculate Financial Impact?:

When measuring ROI, it's crucial to accurately calculate the financial impact of the IIoT project. This involves assessing both direct and indirect benefits. Direct benefits might include cost savings due to reduced downtime or optimized resource utilization. Indirect benefits may encompass increased revenue, improved customer satisfaction, and enhanced competitiveness in the market. By quantifying the financial impact, businesses can provide tangible evidence of the project's value to stakeholders.

6. Continuous Monitoring and Improvement?️:

Measuring ROI is not a one-time activity; it requires continuous monitoring and improvement. As the IIoT project progresses, businesses must continuously track the identified KPIs and analyze the data generated. Regular analysis helps identify areas for improvement, refine strategies, and make informed decisions to ensure maximum ROI and long-term success.

7. Communicate Results and Learnings?:

Effective communication of the IIoT project's results and learnings is vital for showcasing its success and justifying further investments. Sharing the achieved ROI, improvements in key metrics, and valuable insights gained from the project builds trust and confidence among stakeholders. Transparent communication fosters a culture of innovation and encourages more significant investments in future IIoT initiatives.

Conclusion:

Measuring the ROI of an IIoT project is a critical aspect of ensuring its success and sustainability. By setting clear objectives, identifying relevant KPIs, establishing baseline metrics, leveraging real-time data analytics, calculating the financial impact, and continuously monitoring and improving, businesses can effectively measure the ROI of their IIoT projects. Effective ROI measurement justifies investments, optimizes business outcomes, and paves the way for future IIoT advancements. Digi2O is committed to assisting businesses in achieving their IIoT goals and maximizing ROI.

Reach out to our experts to discover how our solutions can help unlock the full potential of your industrial operations. Embrace the power of IIoT and drive your business towards growth and success.

Embracing Industry 4.0: The Revolution that Cuts Costs and Improves Quality

The advent of Industry 4.0 has brought forth a new era of possibilities for businesses. This fourth industrial revolution, characterized by the seamless integration of cyber-physical systems, cloud computing, and the Internet of Things (IoT) into manufacturing processes, holds the key to transforming how businesses operate and enhance their production quality while significantly reducing the dreaded Cost of Poor Quality (COPQ).

Early Detection and Swift Correction with Industry 4.0 Technologies

One of the paramount advantages of embracing Industry 4.0 technologies lies in the power to identify and rectify quality issues at their nascent stages during the production process. By doing so, the occurrence of defects is greatly diminished, leading to substantial cost reductions. Central to this approach are cutting-edge technologies such as sensors, data analytics, and machine learning algorithms that actively monitor the production process in real-time, alerting operators to potential quality concerns even before they escalate into major problems.

Predictive Maintenance: Ushering in an Era of Efficiency

IoT-enabled sensors and analytics play a pivotal role in implementing predictive maintenance strategies that ensure that the machines and processes run with the necessary capability to produce within tolerance specifications and eliminate defects and defectives. This reduces scrap and network costs .

Automation: The Guardian of Uncompromising Quality

Automation, as facilitated by Industry 4.0, emerges as a key contributor to curbing COPQ. Implementing sensors and machine learning algorithms allows businesses to oversee product quality in real-time and promptly halt production lines when substandard items are detected. This level of automation ensures that every product leaving the production line adheres to the required specifications, drastically lowering the likelihood of customer complaints, product returns, and damage to the brand's reputation, thus securing revenue streams.

Data-Driven Decision Making: Identifying and Addressing Quality Issues

Industry 4.0 empowers businesses with an invaluable tool: data-driven decision making. By harnessing and analyzing data collected throughout the production process, businesses can swiftly identify and address potential quality issues before they have a chance to materialize. This proactive approach greatly minimizes the risk of defects and the associated costs, ensuring that products meet or exceed customer expectations consistently.

Digi2O: Your Partner in the Industry 4.0 Journey

At Digi2O, we recognize the fundamental importance of quality in manufacturing and its direct influence on a business's bottom line. Our team of experts is committed to supporting businesses in their implementation of Industry 4.0 technologies, with the primary aim of reducing COPQ, enhancing operational efficiency, and ultimately driving profitability.

Conclusion

In conclusion, Industry 4.0 presents a transformative opportunity for businesses to revolutionize their operations, bolster production quality, and significantly cut down on the Cost of Poor Quality. By incorporating advanced technologies, embracing automation, and fostering data-driven decision making, businesses can embark on a path of continuous improvement, all while reaping the rewards of enhanced efficiency and customer satisfaction.

If you're ready to embark on this exciting journey towards an optimized production process, feel free to get in touch with us at Digi2O today. Let's collaborate in crafting a brighter future for your business through the power of Industry 4.0. Together, we can minimize COPQ and maximize success!

Designed by W3Squad