In a Mckinsey survey of 300 IoT practitioners, 40% identified that discovering and determining use cases and applications as a major capability gap for them. 48% mentioned managing data was another.

Such gaps can, and do, contribute to IoT implementation failures. A study by Cisco found that only 26% of the surveyed companies were successful with their IoT initiatives.

So, do we abandon IoT?

That is not an option.

Consider why: The Mckinsey survey also showed that IoT leaders gained significantly from their IoT projects. Even the IoT laggards claimed reasonable gains.

At Digi2O, we believe that the decision making process can be simplified using a basic framework that can ensure a very high probability of success. Suffice is to say that proper strategy and good planning are the keystones of a successful IoT implementation.

IoT projects are essentially data projects. Installing an IoT solution, without giving sufficient thought to why you are collecting the data and what you will do with the data, can be a recipe for disaster.

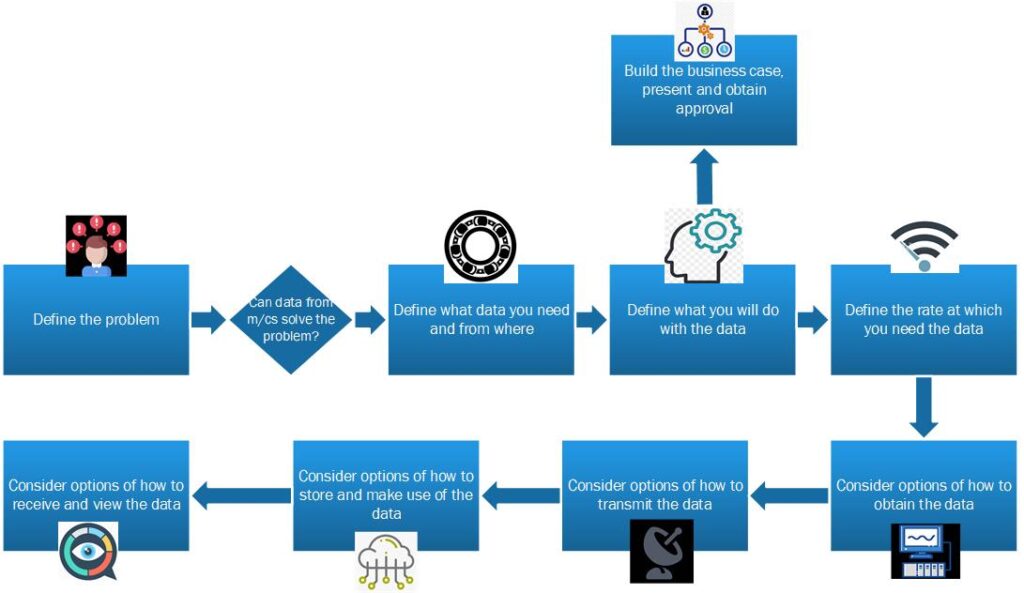

Below is a view of the framework which we use. It is simple but not simplistic. Zooming into each of the boxes in detail and executing them correctly can help you achieve your IoT objectives with a higher success rate.

I will be happy to speak with you if want to know more about how to go about your IoT project.

Meanwhile, I would like to know about your areas of concern, if any, so that we can serve the community better. Please write back to me in the comments section.

Digital twins are everywhere these days, but are you confused by the hype? Here are 5 key insights to separate fact from fiction⭐:

Digital twins have become a buzzword in various industries, from manufacturing to healthcare. These virtual replicas of physical assets or systems are touted for their ability to enhance efficiency, predict maintenance needs, and optimize performance. But what exactly are digital twins, and what should you know about them that isn't commonly discussed? Let's dive into the five key truths about digital twins that often go unnoticed.

When people think of digital twins, they often envision a single, all-encompassing virtual model. However, the reality is far more complex. Digital twins come in many forms, each tailored to a specific purpose. For example, a digital twin of a jet engine might be designed to predict maintenance needs by continuously monitoring performance data. In contrast, a digital twin for a new product design might help engineers optimize performance by simulating various scenarios.

Digital twins are not a one-size-fits-all solution. They are highly specialized tools designed to address specific challenges and objectives. This diversity in application means that businesses can leverage digital twins in numerous ways, depending on their unique needs and goals.

It's a common misconception that any 3D model or digital representation of a physical object qualifies as a digital twin. However, true digital twins have distinct characteristics that set them apart. The most critical feature is the existence of a real-world counterpart with which the digital twin maintains a two-way flow of information.

Imagine a digital twin as a dynamic entity that constantly learns and evolves based on real-time data from its physical counterpart. For instance, a digital twin of a manufacturing machine would continuously receive data on wear and tear, usage patterns, and environmental conditions. This information allows the digital twin to make accurate predictions and provide actionable insights.

Many people assume that digital twins must cover the entire lifecycle of a product or system. While this is one possible application, it's not always necessary or practical. Digital twins can be designed for specific stages of a product's lifecycle, focusing on particular goals or challenges.

For example, during the construction phase of a building, a digital twin might be used to optimize energy use. Once the building is completed, another digital twin could be created to monitor and improve its efficiency during operation. Similarly, in manufacturing, digital twins can optimize factory production processes or enhance post-sales service and support.

The term "digital twin" often conjures images of complex physics simulations and intricate models. While some digital twins do rely on detailed physics-based simulations, this is not a universal requirement. The key is to choose the right tool for the job.

Consider a digital twin for a new clothing design. In this case, visual similarity and data analysis might be more important than simulating physical behavior. On the other hand, a digital twin for a self-driving car would need to rely heavily on physics simulations to accurately model real-world behavior and ensure safety.

Digital twins are not just for engineers! This versatile technology has applications far beyond the realm of engineering. For example, financial services companies can use digital twins to model market trends and predict the impact of various economic scenarios. Similarly, logistics companies can leverage digital twins to optimize their supply chain operations, reducing costs and improving efficiency.

The potential applications of digital twins are limited only by our imagination. By thinking creatively and exploring new use cases, businesses across different industries can unlock the full potential of this transformative technology.

Digital twins represent a significant advancement in how we model, monitor, and optimize physical assets and systems. However, it's crucial to understand that there is no one-size-fits-all approach, and not all digital models qualify as true digital twins. By focusing on specific purposes rather than lifespans, choosing the right tools, and exploring applications beyond engineering, businesses can fully leverage the power of digital twins.

Warehouse automation is on the rise, but there's a lot of misinformation out there. Are robots too expensive? Will they take all our jobs? Here's a look at 10 common myths debunked🧐:

Myth #1: Bank Breaker Bots💸?

While upfront costs can seem high, financing options and rapid return on investment (ROI) make robots more affordable than ever.

Myth #2: Robot Programming Nightmare😥?

Nope! Modern robots are designed for easy use with cloud-based software and user-friendly interfaces.

Myth #3: Hacker Haven⚠️?

Reputable vendors prioritize security with features like encryption and access controls to keep your operations safe.

Myth #4: Inflexible Machines🫤?

Today's robots are highly adaptable, taking on tasks like picking, sorting, and transporting goods as your needs evolve.

Myth #5: Integration Impossible🤔?

Modern robots work seamlessly with existing warehouse management systems (WMS) thanks to open architecture and experienced automation teams.

Myth #6: Robots vs. Humans⚔️?

Actually, robots are teammates! They handle repetitive tasks, freeing up human workers for strategic thinking and problem-solving.

Myth #7: Job Destroyer 3000🫨?

Warehouse robots create new opportunities! They eliminate dangerous and tedious jobs, allowing humans to focus on higher-value activities.

Myth #8: Safety Last🤕?

Safety is a priority. Robots come equipped with features like LiDAR and collision avoidance sensors to keep everyone safe.

Myth #9: Error Avalanche😵?

Robots follow instructions precisely, minimizing errors. Built-in checks and balances prevent mistakes from multiplying.

Myth #10: Support MIA😶🌫️?

Experienced vendors offer comprehensive support, including training and technical assistance to ensure you get the most out of your robots.

Ready to explore the future of warehouse automation?

The advent of Artificial Intelligence (AI) has revolutionized industries, particularly manufacturing. The future is smart, connected, and data-driven, ushering in the era of Industry 4.0. But amidst the hype, what does a successful AI implementation truly look like? Here are five essential facts that every business should consider to effectively integrate AI into their manufacturing operations.

Before diving into AI, it's crucial to start with a clear vision and a strategic plan. Analyze your current operations and identify specific areas where AI can deliver the most value. For instance, predicting equipment failure to avoid costly downtime or personalizing production lines for mass customization. These targeted applications can significantly enhance efficiency and productivity.

A well-defined vision sets the foundation for AI integration. It involves understanding the unique challenges and opportunities within your manufacturing processes. This step requires:

With a vision in place, the next step is to develop a detailed plan. This plan should outline:

AI systems are only as good as the data they process. Ensuring your data is clean, consistent, and relevant to the problem you're trying to solve is paramount. Imagine an AI system attempting to optimize production with inaccurate machine sensor data – the results would be chaotic and ineffective.

High-quality data is the backbone of effective AI. To achieve this, businesses must:

Not all data is useful. It's essential to filter and use data that aligns with your specific AI objectives. This involves:

People are the key to successful AI implementation. Preparing your workforce for the transition and addressing concerns about job displacement are critical steps. Upskilling employees to work alongside AI can lead to better decision-making and more efficient operations.

Change management involves:

AI often brings fears of job loss. To mitigate this, businesses should:

As you connect machines and collect data, cybersecurity becomes critical. Investing in robust security measures protects your operations and intellectual property. The nightmare of a hacker taking over your robots is a real threat that requires vigilant safeguarding.

Effective cybersecurity involves:

AI in manufacturing often involves proprietary algorithms and data. To safeguard intellectual property:

AI implementation is an ongoing process. Continuously monitor and refine your systems to ensure they deliver long-term benefits. Think of it as constantly improving your AI models for better performance and efficiency.

To sustain AI benefits, businesses should:

A successful AI journey requires:

Embracing AI in manufacturing is not a decision to be taken lightly. It involves a strategic approach, robust data management, effective change management, stringent security measures, and a commitment to continuous improvement. By following these five key takeaways, businesses can navigate the complexities of AI integration and unlock its full potential to revolutionize their operations.

The future of manufacturing is no longer about mere automation; it's about intelligence. Enter Artificial Intelligence (AI), a game-changer that promises to revolutionize manufacturing. AI is portrayed as the ultimate solution for enhancing efficiency, reducing costs, and improving quality in manufacturing processes. But beneath the glitz and glamour, there’s a reality about AI implementation that often goes unspoken.

In this comprehensive article, we’ll explore five critical truths about AI implementation in manufacturing that no one tells you. These truths debunk common myths and provide a realistic perspective on the challenges and strategies associated with integrating AI into your manufacturing operations.

AI thrives on data – it’s the lifeblood of machine learning models. But here's the catch: not all data is created equal. High-quality, labeled data is essential for training effective AI systems. Manufacturers often struggle to gather sufficient data, particularly when it comes to anomalies like defective products. This data scarcity can stall AI initiatives.

Example: Imagine you're developing an AI system to identify defective products on a production line. To train this system, you need thousands of images of defective items. However, defects are often rare, making it hard to accumulate enough examples for robust training.

Labeling data is another bottleneck. It’s not just about collecting data but also annotating it, which can be time-consuming and expensive. Manual labeling is labor-intensive and requires expertise to ensure accuracy. Moreover, data privacy regulations add another layer of complexity, necessitating secure handling and storage of data.

To tackle these challenges:

The demand for AI talent far exceeds the supply. Finding skilled AI professionals – data scientists, machine learning engineers, and AI specialists – is a significant hurdle. The market is fiercely competitive, and salaries for top talent can be exorbitant.

Example: A mid-sized manufacturing company looking to hire an AI engineer may find that the candidates are either overqualified (and thus too expensive) or lack the specific industry knowledge needed to be effective.

Even when you find potential hires, there's often a skills mismatch. Many AI professionals are trained in academic or tech settings and may not understand the intricacies of manufacturing environments. They might excel in theoretical AI but struggle with practical application in a factory setting.

A successful Proof of Concept (PoC) can be misleading. It demonstrates that AI can work in a controlled environment, but scaling it to production involves a different set of challenges. The transition from PoC to production is fraught with technical, logistical, and operational hurdles.

Example: An AI system for predictive maintenance might work perfectly in a PoC setting. However, scaling it across multiple machines and integrating it with existing systems can reveal unforeseen complications, such as compatibility issues and data integration problems.

Unlike traditional software, AI systems are dynamic and evolving. They require constant monitoring, updates, and retraining to remain effective. Data changes, environments evolve, and new challenges emerge, necessitating ongoing maintenance.

Example: An AI system for quality inspection might initially perform well but could degrade over time if it’s not updated to recognize new types of defects or changes in product design.

While the cloud offers numerous advantages for AI, including scalability and accessibility, it’s not always the ideal solution for every manufacturing environment. Issues like internet reliability, latency, and data security can make cloud-based AI impractical for real-time applications.

Example: In a remote factory with unreliable internet access, relying on cloud-based AI for real-time machine control could lead to latency issues, potentially disrupting production.

Edge computing offers a viable alternative by processing data locally on devices rather than relying on the cloud. This approach reduces latency and dependency on internet connectivity, making it suitable for real-time decision-making in manufacturing.

AI in manufacturing is transformative but not without its challenges. Understanding the realities of data collection, talent acquisition, PoC transition, system maintenance, and cloud dependency is crucial for successful AI implementation. By addressing these often-overlooked truths, manufacturers can navigate the complexities of AI adoption and unlock its full potential.

Are you ready to embrace the AI revolution? Share your experiences and strategies in the comment box below, and join the conversation on how to leverage AI for supercharging your manufacturing operations. ????

Is Your Leadership Stuck in the Past?????

In a rapidly evolving business landscape, clinging to outdated leadership styles can be detrimental. The digital age demands a new breed of leaders who can navigate disruption and harness the power of technology. Does your leadership team possess the vision required for this transformation? If not, it’s time to cultivate a future-proof mindset.

The future demands future-proof leaders!????

Strategic Vision????️: The Power of Big Picture Thinking

To succeed in the digital age, leaders must possess a strategic vision. This means having the ability to see the big picture and understanding how technology can transform their organization. Imagine a CEO who leverages data analytics to predict market trends and automates routine tasks to streamline operations. This approach not only enhances efficiency but also positions the company ahead of its competitors.

Strategic vision involves:

For example, Amazon’s Jeff Bezos has consistently demonstrated strategic vision by integrating technology into every aspect of the company, from logistics to customer service, ensuring Amazon remains a market leader.

Collaboration & Trust????: Building a Culture of Innovation

Innovation thrives in a collaborative environment. Leaders must foster a culture where diverse ideas can flourish. Think of a leader who empowers their teams to share ideas freely and creates a safe space for experimentation. This approach not only sparks creativity but also builds trust within the organization.

Key aspects of collaboration and trust include:

A great example is Satya Nadella of Microsoft, who transformed the company’s culture to one of collaboration and inclusivity, leading to increased innovation and growth.

Customer-Centric Focus⭐: Putting the Customer First

In today’s market, customers are the king. Leaders must adopt a customer-centric approach, building strong communities around their brand. Picture a leader who actively engages with customers on social media, gathers their feedback, and uses it to develop new products and services.

Customer-centric focus entails:

Apple’s Tim Cook exemplifies this trait by maintaining Apple’s tradition of exceptional customer service and continuously innovating based on customer feedback.

Continuous Learning????: Staying Ahead of the Curve

The digital age demands constant learning. Leaders must be curious, adaptable, and open to new knowledge. Imagine a leader who actively seeks out industry trends, listens to experts, and isn’t afraid to admit they don’t know everything. This humility and eagerness to learn keep leaders and their organizations ahead of the curve.

Continuous learning involves:

Elon Musk, CEO of SpaceX and Tesla, is a prime example of a leader who embodies continuous learning. His relentless pursuit of knowledge and innovation has led to groundbreaking advancements in both industries.

Invest in the Future: Developing Digital Age Leaders????

Developing leaders who can conquer the digital age is crucial for organizational success. Here are some steps to cultivate a future-proof leadership mindset:

Conclusion: The Path to Future-Proof Leadership

The digital age presents both challenges and opportunities for industry leaders. By adopting a future-proof mindset, leaders can navigate disruption, harness the power of technology, and drive their organizations toward sustained success. Embracing strategic vision, fostering collaboration and trust, maintaining a customer-centric focus, and committing to continuous learning are key traits that will define the leaders of tomorrow.

Investing in the development of these traits within your leadership team will not only future-proof your organization but also ensure it thrives in the dynamic business landscape of the digital age.

Designed by W3Squad